Cold Blade vs Heated Blade in Ribbon Cutting: When to Switch & How to Maintain

In our previous guide on Hot vs Cold Cutting, we discussed the results. Today, we are going deep into the hardware. As a factory owner, you might be asking: "Do I need two separate machines, or can one machine do both?"

The choice between a Cold Blade and a Heated Blade depends on the material’s melting point and thickness. A Cold Blade acts like a high-speed guillotine for natural fibers and Velcro hooks, while a Heated Blade acts as a cauterizing iron for synthetics. Modern machines often feature interchangeable or dual-blade systems to maximize factory versatility.

At HAOXINHE, we see many clients buying the wrong blade configuration. They buy a dedicated hot cutter, then get an order for cotton tape and realize they cannot cut it without burning it. This guide will explain the engineering differences so you buy the right webbing tape cutting machine1 the first time.

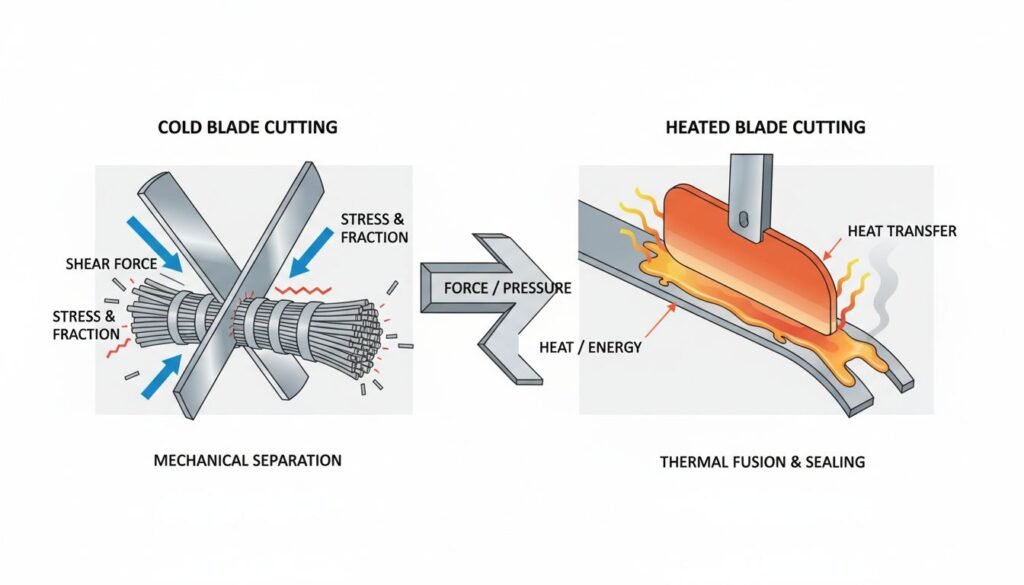

Why Blade Temperature Matters More Than Sharpness

For a Cold Blade, sharpness is everything. It works on "Shear Stress2." The upper blade passes the lower blade with zero gap, slicing the fibers. If the blade is dull, it "chews" the fabric.

For a Heated Blade3, temperature is everything. Sharpness is secondary. In fact, a slightly dull hot blade often seals better because it has more surface area to transfer heat. It works on "Thermal Fusion4."

The "Velcro Paradox"

Velcro (Hook and Loop) is the perfect example of why you might need both.

- The Loop Side (Soft): Usually needs a Hot Blade to seal the backing and prevent fraying.

- The Hook Side (Hard): Often needs a Cold Blade. Why? Because a hot blade can melt the plastic hooks into a solid lump, ruining the grip.

- The Solution: A dual-mode hot and cold cutting machine where you can turn the heater off or swap the blade.

Deep Dive: Engineering Differences

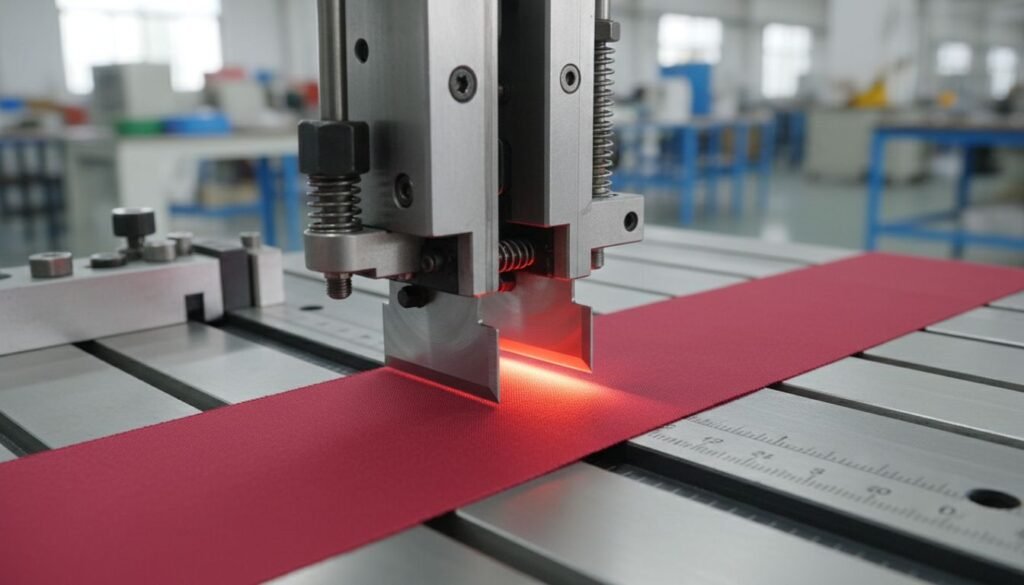

Here is the technical breakdown of how these blades function inside an industrial machine like our Cutopix series.

1. The Cold Blade System

Found in our computer tube cutting machine and wire cutting and stripping machine.

- Material: High-Speed Steel (HSS) or Tungsten Carbide.

- Action: Scissor-like reciprocating motion.

- Speed: Extremely fast (up to 140 cuts/min) because it doesn’t need "dwell time."

- Maintenance: Requires sharpening every 1-2 months depending on usage.

- Key Application: PVC Edge Banding cutting machine5, paper, cotton, zipper chains.

2. The Heated Blade3 System

Found in our ribbon and HX-160HL Parachuting Climbing Webbing Rope Cutting Machine6.

- Material: Special alloy steel capable of withstanding 500°C without warping.

- Action: Vertical chop or hot-wire slice.

- Speed: Limited by physics. The blade must sit on the material for 0.3-0.5 seconds to transfer heat.

- Maintenance: Cleaning is critical. Melted plastic builds up (carbonization) and insulates the blade, causing cold spots.

- Key Application: Nylon, Polyester, Polypropylene.

[https://cutopix.com/product/hot-cold-ribbon-label-plastic-cutting-machine-hx-95m/ [Hot and Cold Cutting Machine Series]

Industrial / Manufacturing Considerations

If you are a factory manager like Mark, you care about Uptime and Versatility.

The "Combo" Machine Advantage

For contract manufacturers who handle different orders every week, we recommend a Cold & Hot Combined Tape Cutting Machine7.

- Scenario A: Monday you cut satin ribbons for a gift company. You turn the heater ON (250°C).

- Scenario B: Tuesday you cut cotton twill tape for tote bags. You turn the heater OFF.

- Scenario C: Wednesday you cut heat-shrink tubes. You use the Cold setting.

This saves you from buying two separate machines and taking up double the floor space.

Maintenance Protocols

- Cold Blades: Check for "burrs" or nicks in the metal. If the blade is chipped, it will snag the fabric.

- Hot Blades: Check for black residue. Use a brass brush to clean the blade while it is hot (carefully!). Do not use a steel file, or you will damage the coating.

How Machines Solve This Problem

At HAOXINHE, we engineer our machines to handle the stress of both cutting types.

The HX-980 Series Logic

Our microcomputer controller allows you to adjust not just length and speed, but Blade Behavior.

- Cold Mode: The motor drives the blade instantly.

- Hot Mode: The motor pauses the blade at the bottom of the stroke for a programmable time (e.g., 0.5s) to ensure sealing.

For heavy-duty applications like climbing ropes, standard hot blades aren’t enough. That is why our HX-160HL Parachuting Climbing Webbing Rope Cutting Machine6 uses a massive, high-mass heated blade that stores thermal energy, preventing the temperature from dropping even when cutting 20mm thick ropes.

[HX-160HL Parachuting Climbing Webbing Rope Cutting Machine6]

Conclusion

To summarize, the blade type dictates your production capability. Cold blades are for speed and natural fibers; heated blades are for sealing synthetics. The smartest investment for a versatile factory is a machine that can do both.

Cherry’s Insights for Google Snippet

A Cold Blade cuts by mechanical shearing and is ideal for natural fibers (Cotton, Jute) and non-melting plastics (PVC, Velcro Hooks), offering high speed and clean cuts. A Heated Blade cuts by thermal fusion, essential for sealing synthetic fibers (Polyester, Nylon) to prevent fraying. For factories handling mixed materials, HAOXINHE recommends a dual-mode ‘Hot and Cold’ cutting machine, allowing operators to switch between cutting methods instantly without changing equipment.

-

Explore the features of webbing tape cutting machines to enhance your production efficiency. ↩

-

Explore the concept of Shear Stress to improve your cutting techniques for natural fibers. ↩

-

Learn how Heated Blades work to seal synthetic materials effectively. ↩ ↩

-

Understanding Thermal Fusion can help you optimize your cutting processes for synthetic materials. ↩

-

Discover how PVC Edge Banding machines can improve your cutting precision. ↩

-

Learn about this specialized machine designed for heavy-duty applications. ↩ ↩ ↩

-

Find out how a combined machine can save space and increase versatility in your factory. ↩