Cutting Packaging Materials: Bubble Wrap & EPE Foam Sheets

Textile factories often ignore the "Packaging Department." You have high-tech machines for your product, but your workers are still cutting Bubble Wrap and EPE Foam1 sheets with hand scissors on the floor. This is slow, messy, and wastes huge amounts of packing material.

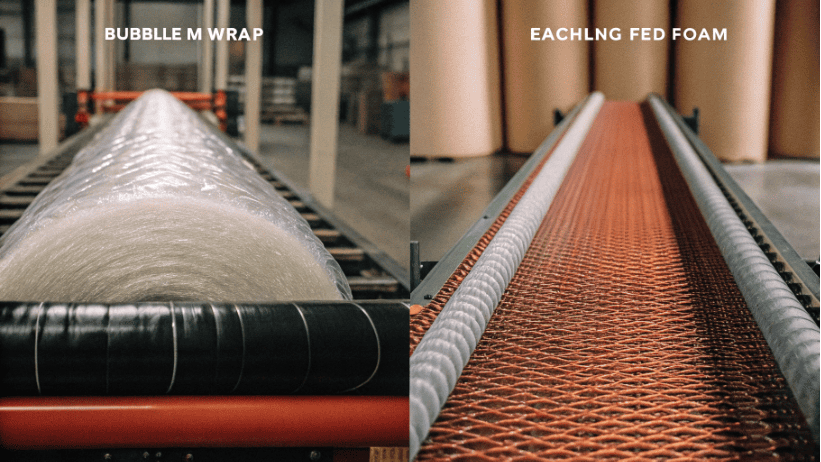

To cut Bubble Wrap and EPE Foam efficiently, you need a "Sheet Cutting Machine" with a Cold Guillotine Blade and a wide format (usually 500mm to 1000mm). Unlike ribbon cutters, these machines use "Belt Feeding" systems to transport the delicate, air-filled material without popping the bubbles or crushing the foam.

I am Cherry from HAOXINHE. We supply Protective Foam Cutting Machine solutions to logistics centers and electronics factories. Let’s clean up your packing process.

Why Standard Ribbon Cutters Fail Here

You cannot put Bubble Wrap through a standard webbing tape cutting machine.

- Too Narrow: Webbing machines are 100mm wide. Bubble wrap rolls are 500mm+.

- The Crush: Ribbon machines use pinch rollers. These will pop the bubbles or permanently compress the EPE foam, destroying its protective value.

- Static: Foam and bubble wrap are static generators. They will stick to standard metal chutes and cause jams instantly.

Deep Dive: The Sheet Cutting Technology

You need a machine designed for "Volume" not "Tensile Strength."

1. Belt Feeding2 System

Instead of two rollers pinching the material, we use Rubber Conveyor Belts3 (Top and Bottom).

- Benefit: The belts have a large surface area. They grip the foam gently over a wide area, providing traction without crushing.

- Accuracy: This allows us to cut EPE foam sheets to ±1mm length accuracy.

2. The Guillotine Blade (Cold)

We use a wide, heavy cold blade.

- Action: It chops vertically.

- Why Cold? If you use heat on bubble wrap, it melts into a sticky plastic line. You want the bubbles to remain inflated right up to the cut edge.

3. Static Elimination4 (Crucial)

As mentioned in Day 7, static is a nightmare. For big sheets of foam, it’s even worse.

- Solution: We install massive Ionizer Bars across the entire width of the exit chute to ensure the sheets slide into the bin.

[👉 INSERT LINK: Protective Foam Cutting Machine]

[👉 INSERT LINK: Bubble wrap cutting machine]

Industrial / Manufacturing Considerations

The "Memory" of Foam

EPE Foam1 comes on a roll. It has a "curl." When you cut it, it wants to roll back up.

- Flattening: Our machines have adjustable "Flattening Bars" at the inlet to take the curl out of the foam before it is measured. This ensures the cut length is accurate when the sheet lies flat.

Lightweight Material Handling

Cut pieces of bubble wrap act like feathers. They float.

- Stacking: You cannot rely on gravity. You often need an Auto-Stacker Conveyor that catches the sheet and presses it down into a pile.

How Machines Solve This Problem

The HAOXINHE HX-Sheet Series is built for width.

- Max Width: Up to 1500mm.

- Max Thickness: Can cut EPE foam up to 20mm thick.

- Programmable Batches: You can set it to cut 50 sheets for Box A, then pause, then cut 20 sheets for Box B.

This same machine can also cut Insulation Paper, PET Film, and Kraft Paper. It is a utility player for your shipping department.

Conclusion

To summarize, stop paying people to cut bubble wrap by hand. It is the lowest value task in your factory. A dedicated wide-format cutter ensures every box gets the exact amount of protection—no more, no less—saving you material costs and packing time.

📦 Industry Insight: Why Manual Cutting Is Costing You More Than You Think

After working with dozens of logistics and electronics factories, we’ve found that manual cutting of bubble wrap is the #1 hidden cost in the packaging department. The labor seems cheap, but it leads to inconsistent sizing, wasted material, and poor stacking—all of which affect shipping efficiency and damage rates.

One overlooked issue? “Foam memory.” EPE foam wants to curl back into a roll after cutting, which leads to under-padded corners during transit. Machines with flattening bars solve this at the inlet stage—something scissors or utility knives can’t do.

Also, static isn’t just a nuisance—it’s a workflow blocker. We’ve seen entire lines grind to a halt because cut sheets clung to chutes or sensors. That’s why professional setups use wide ionizer bars and stackers to control this from the first to the last sheet. Packaging may be the last step, but it defines the first impression when your product arrives.

-

Learn about EPE Foam’s properties and its critical role in protective packaging solutions. ↩ ↩

-

Discover how Belt Feeding systems enhance the efficiency and quality of cutting processes. ↩

-

Find out why Rubber Conveyor Belts are preferred for handling delicate materials in cutting machines. ↩

-

Understand the importance of Static Elimination and how it prevents workflow disruptions in packaging. ↩