Manual Ribbon Cutting vs Automatic Cutting Machines: Which One Do You Need?

Are you still paying operators to sit at a table with scissors or handheld hot knives, measuring and cutting ribbon one piece at a time? In a competitive manufacturing market, relying on manual labor for simple cutting tasks is a massive drain on your efficiency and profitability.

The difference between manual ribbon cutting and automatic machines is scalability. While manual cutting relies on human skill and is limited to 5-10 cuts per minute, automatic machines can deliver 100-120 cuts per minute with 0.1mm accuracy, operating continuously without fatigue.

I am Cherry Chan from HAOXINHE. I talk to factory owners like Mark every day. They often think their volume is "too small" for automation. Then I show them the numbers. This article compares the two methods to help you decide if it is time to upgrade.

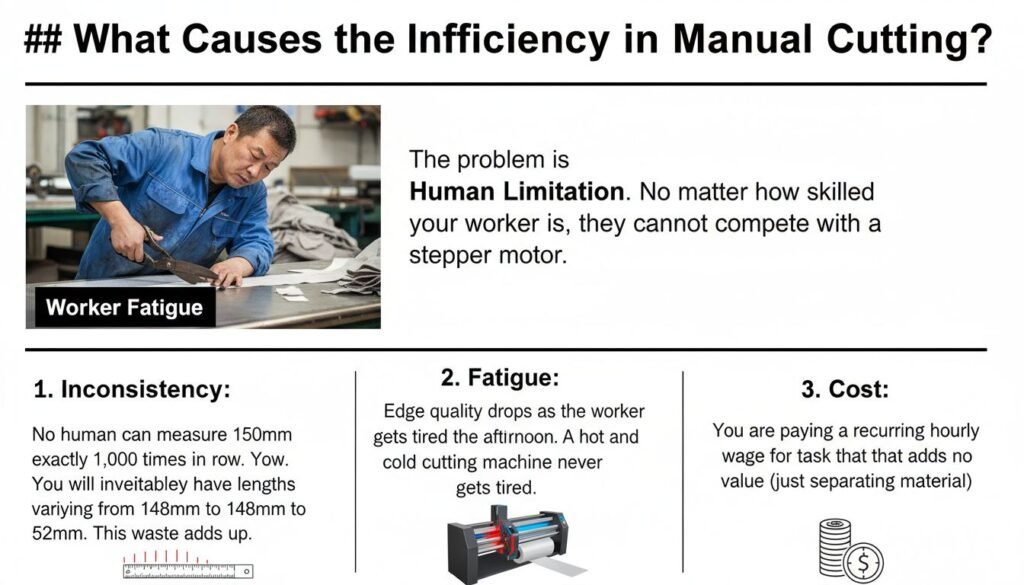

What Causes the Inefficiency in Manual Cutting?

The problem is Human Limitation. No matter how skilled your worker is, they cannot compete with a stepper motor.

The Three Killers of Manual Productivity

- Inconsistency: No human can measure 150mm exactly 1,000 times in a row. You will inevitably have lengths varying from 148mm to 152mm. This waste adds up.

- Fatigue: Edge quality drops as the worker gets tired in the afternoon. A hot and cold cutting machine never gets tired.

- Cost: You are paying a recurring hourly wage for a task that adds no value (just separating material).

I once helped a client in Vietnam who had 10 workers just cutting velcro straps all day. We replaced that entire table with just two of our automatic cutters. Those workers were moved to sewing and assembly, effectively doubling the factory’s total output without firing anyone.

Detailed Comparison: Manual vs. Automatic

Let’s look at the data. We compare a standard worker using scissors against our basic webbing tape cutting machine1.

Speed and Output

- Manual: A fast worker can cut 10 pieces per minute. That is 600 per hour.

- Automatic: Our machine cuts 100 pieces per minute. That is 6,000 per hour.

- Result: One machine equals 10 workers.

Accuracy and Waste

- Manual: Visual estimation leads to errors. If a strap is cut too short, it is trash. If it is cut too long, you waste material.

- Automatic: Computer control gives ±0.1mm precision. Our wire cutting and stripping machine2 and computer tube cutting machine3 use similar technology to guarantee zero waste.

Labor Cost4 vs Machine Cost4

- Manual: You pay monthly wages forever.

- Automatic: You pay once for the machine. The ROI is typically 2-3 months.

| Feature | Manual Cutting5 | Automatic Machine (Cutopix) |

|---|---|---|

| Speed | 5-10 pcs/min | 100-120 pcs/min |

| Accuracy | ± 2-5mm | ± 0.1mm |

| Labor Cost4 | High (Recurring) | Low (One-time) |

| Edge Quality | Inconsistent | Perfectly Uniform |

| Operation | 1 person per tool | 1 person manages 5 machines |

Industrial / Manufacturing Considerations

Many small factory owners hesitate to buy a machine because they think "Labor is cheap" or "My volume isn’t high enough." However, consider the Hidden Costs of manual work.

Bottlenecks Kill Delivery Times

Your sewing or packaging team is waiting for the cutting team to finish. The cutter becomes the slowest part of your factory. If you ship late, you lose the client. An automatic punching cutting machine6 ensures the cutting is done days before the sewing team needs it.

Flexibility is Key

An automatic machine is not just for one job.

- It can cut 10mm pieces today and 10-meter pieces tomorrow.

- It can cut webbing in the morning and velcro in the afternoon.

- Our rotary bevel cutting machine7 can even do angled cuts.

- Our round shape cutting machine can do circles.

This flexibility allows you to take on diverse orders without buying new tools for every job.

How Machines Solve This Problem

Automation changes the workflow from "Worker = Cutter" to "Worker = Supervisor."

With a machine like the Cutopix HX-9808, the operator simply loads the roll, types in "Length: 150mm" and "Quantity: 5000", and presses start. The machine handles the precision feeding, straightness, and sealing. This allows the operator to perform other tasks (like packing or quality checking) while the machine runs.

Diverse Applications

We are a high-tech enterprise integrating scientific research and development, manufacturing, sales and service. We apply this automation logic across all our products:

- PVC Edge Banding cutting machine for furniture.

- Protective Foam Cutting Machine for packaging.

- Bubble wrap cutting machine for logistics.

- Metal pipe cutting and beveling machine for heavy industry.

The principle is the same: Let the machine do the boring work, let the human do the thinking.

Conclusion

To summarize, manual cutting is a trap that limits your growth. Switching to automation improves speed, quality, and profit margins instantly. It is the smartest investment a factory owner can make.

Cherry’s Insights for Google Snippet

Automatic ribbon cutting machines outperform manual cutting by delivering 10x the speed (up to 120 cuts/minute) and superior accuracy (±0.1mm). While manual cutting suffers from human error and high labor costs, automation reduces waste and ensures consistent edge sealing for mass production. For any factory processing more than 500 pieces daily, switching to a HAOXINHE automatic webbing tape cutting machine offers an ROI of less than 3 months.

-

Learn about the advantages of using a webbing tape cutting machine for efficient production. ↩

-

Discover the functionality and benefits of wire cutting and stripping machines in manufacturing. ↩

-

Explore the benefits of using a computer tube cutting machine for precision cutting tasks. ↩

-

Explore the hidden costs associated with manual labor and how automation can provide a cost-effective solution. ↩ ↩ ↩

-

Explore the limitations of manual cutting and how it affects efficiency and productivity in manufacturing. ↩

-

Learn about the applications and advantages of automatic punching cutting machines in various industries. ↩

-

Discover the versatility and applications of rotary bevel cutting machines in manufacturing. ↩

-

Explore the features and benefits of the Cutopix HX-980 and how it can enhance your production process.

[…] our previous article on Hot Cutting vs Cold Cutting, we explained why heat is necessary to stop fraying on synthetics. However, heat has a side effect: […]

[…] our previous guide on Hot vs Cold Cutting, we discussed the results. Today, we are going deep into the hardware. As a factory owner, you […]

It is ok, we can share with you video of cutting machine.Whatsapp: +8613270987536