How to Cut Ribbon from Fabric?

Cutting ribbon manually from fabric is often slow, imprecise, and leads to fraying, uneven widths, or off-grain edges.

To cut ribbon from fabric properly, you need a stable cutting surface, measurement tools, and ideally, an industrial cutting machine that can handle bulk fabric with accuracy.

If you’re producing ribbon in-house—from satin, cotton, organza, or even printed textiles—then you already know the struggle: consistency is hard to maintain. Here’s how to do it right.

How to Have a Successful Ribbon Cutting?

In both manufacturing and ceremonial use, ribbon cutting has to look and feel professional.

A successful ribbon cutting requires clean, precise edges, smooth fabric tension, and proper tools suited to the ribbon type—plus preparation if it’s for a public event.

This applies both to industrial processes and high-visibility ceremonies. In business, success depends on control and repeatability; in events, it’s about visual impact and smooth execution.

Dive Deeper: What’s the Best Way to Cut Ribbon from Fabric?

Many businesses try to create custom ribbon by cutting strips from fabric rolls. But without the right tools, this leads to off-grain cuts, fraying edges, and wasted fabric.

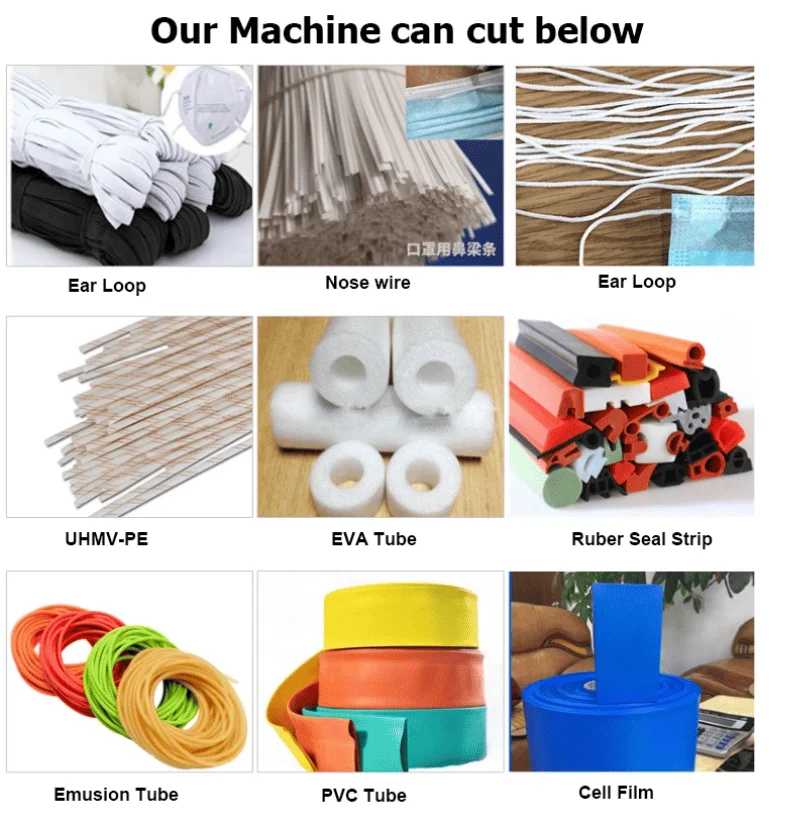

The best way to cut ribbon from fabric is using a machine that can handle both the width conversion and edge sealing in one operation—like a rotary bevel cutting machine or hot/cold cutting machine.

Manual Cutting from Fabric: What You Need

If you’re doing low-volume production or prototyping, this setup will help:

- Cutting Mat: Prevents slippage and helps align fabric

- Ruler or Acrylic Grid: Keeps ribbon strips straight and even

- Rotary Cutter: Gives cleaner edges than scissors

- Fabric Type Consideration:

- Satin & organza require gentle handling

- Cotton frays less but needs sharp blades

However, manual methods are time-consuming and inconsistent.

Industrial Fabric-to-Ribbon Conversion

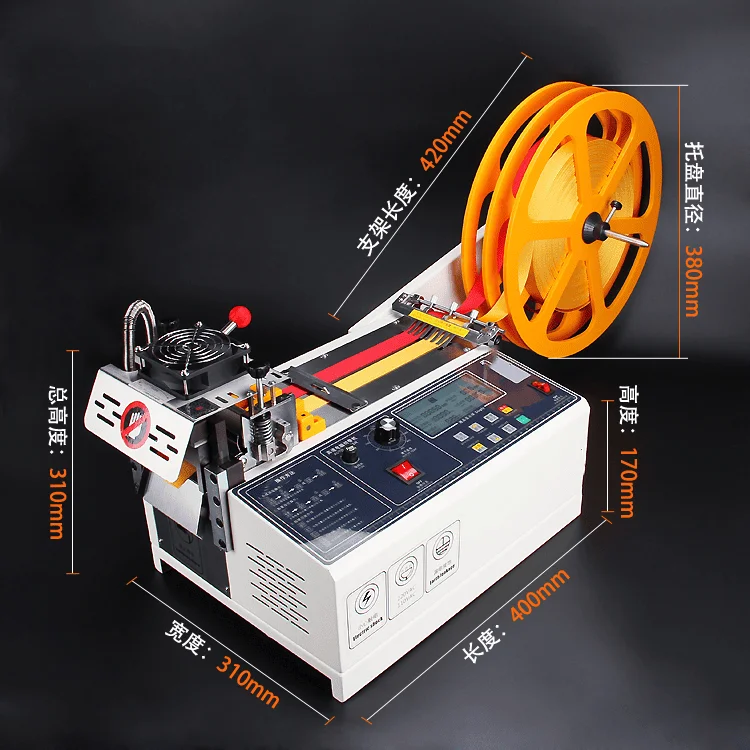

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we help manufacturers turn bulk fabric rolls into professional-grade ribbons. Our machines offer:

- Edge sealing with hot knife technology

- Custom width setting from 5mm to 200mm

- High-speed cutting with auto-feeding

- Anti-fray and anti-curl controls

Recommended Machines

| Machine Model | Best Use Case |

|---|---|

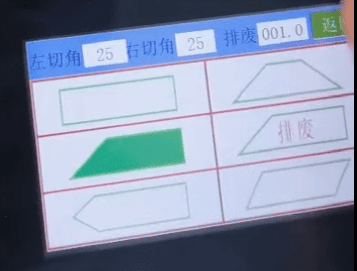

| Rotary Bevel Cutting Machine | Creating ribbons with angled or smooth edges |

| Hot and Cold Cutting Machine | For polyester, satin, or nylon fabrics |

| Automatic Punching Cutting Machine | For patterned ribbons or shaped ends |

| Bubble Wrap Cutting Machine | If using foam-laminated fabrics |

These machines use intelligent control systems to ensure every strip is cut to exact specs—ideal for labels, packaging ribbons, fashion trims, and safety gear.

Dive Deeper: How to Run a Successful Ribbon Cutting Event or Operation?

In manufacturing, a “ribbon cutting” is about product quality. In business events, it’s about presentation. Either way, the ribbon needs to be perfect.

To run a successful ribbon cutting, focus on preparation: choose high-quality ribbon, ensure it’s cut cleanly (no fraying), and test your tools or machines ahead of time.

For Industrial Ribbon Cutting Success

If your “ribbon cutting” refers to daily operations in your production line:

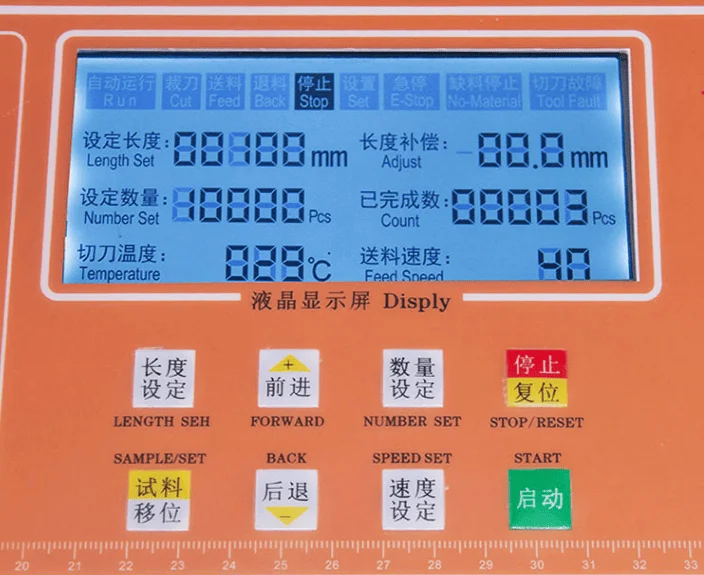

- Use automatic cutting machines for consistency

- Adjust heat settings based on fabric

- Perform regular blade maintenance

- Use fabric sensors for positioning and tension control

For example, in our computer tube cutting machine, built-in sensors detect material length and alignment to avoid miscuts.

Example: One of our clients in Italy switched from manual rotary cutting to our webbing ribbon cutting machine. Within weeks:

- Daily output increased by 3x

- Ribbon width variation dropped from ±2mm to ±0.2mm

- Customer satisfaction improved due to cleaner packaging presentation

For Ceremonial Ribbon Cutting Success

Planning a business event, store opening, or product launch? Here’s how to make the ribbon cutting picture-perfect:

- Use wide satin or grosgrain ribbon (at least 2 inches)

- Cut ends cleanly at an angle or with a V-shape

- Pre-iron the ribbon to remove creases

- Use sharp ceremonial scissors

- Anchor the ribbon securely so it’s taut before cutting

Many of our clients order custom pre-cut ceremonial ribbon using our round shape cutting machine—especially if they’re running a promotion or exhibition.

Conclusion

Whether you’re cutting ribbon from fabric or preparing for a ribbon cutting event, success starts with the right tools and preparation.

Insights

Cutting ribbon from fabric requires more than just scissors—it needs accurate alignment, edge sealing, and clean cutting tools. Suzhou Haoxinhe Electrical Equipment Co., Ltd. offers industrial ribbon cutting machines that convert fabric rolls into consistent, fray-free ribbons with programmable widths and high-speed output. Whether you’re producing custom packaging ribbon or organizing a ceremonial ribbon cutting, our machines deliver reliable quality and professional results.