How to Make Ribbon from Fabric Without Sewing?

Want to turn fabric into ribbon without pulling out a sewing machine? You’re not alone.

You can make ribbon from fabric without sewing by cutting fabric into strips using a rotary cutter or industrial ribbon cutting machine—and sealing the edges with heat to prevent fraying.

This method is fast, clean, and ideal for both small-batch crafting and large-scale manufacturing. Let’s explore how to do this efficiently, with or without machines.

How to Make Torn Fabric Ribbon?

Torn ribbons have a natural, rustic charm—but the process needs some care to get the right texture.

To make torn fabric ribbon, cut a small snip at the fabric’s edge, then pull along the grain to tear it. For clean, fray-controlled edges, you can later heat-seal or trim them as needed.

This style is popular in wedding décor, gift wrapping, and vintage-inspired packaging. But without the right tools or material knowledge, torn ribbons can become messy and unusable.

Dive Deeper: Making Fabric Ribbon Without Sewing – Industrial and DIY Options

If you’re making ribbon from fabric and want to skip sewing, your biggest challenge is edge control.

The key to making ribbon without sewing is clean cutting, followed by heat-sealing if needed. Industrial users should use programmable ribbon cutting machines. Crafters can use rotary blades and edge treatments.

DIY No-Sew Ribbon Method

Perfect for small runs or creative uses:

- Choose tightly woven fabrics like satin, taffeta, or cotton

- Use a rotary cutter and ruler to cut strips

- For synthetic fabrics, seal edges with:

- A lighter (gently pass flame near the edge)

- A hot knife or heated tool

- For natural fabrics (cotton/linen), pinking shears can reduce fray

Pros:

- No sewing machine required

- Custom widths possible

- Good for gifts, labels, decoration

Cons:

- Labor-intensive for large quantities

- Inconsistent results without skill

Industrial No-Sew Ribbon Production

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we help factories and wholesale suppliers produce sewn-free ribbons at scale.

Our webbing ribbon cutting machines and hot and cold cutting machines:

- Cut and seal edges at the same time

- Handle wide fabric rolls (including custom printed textiles)

- Output consistent, high-speed ribbon batches

- Support hot knife, cold knife, and rotary blade options

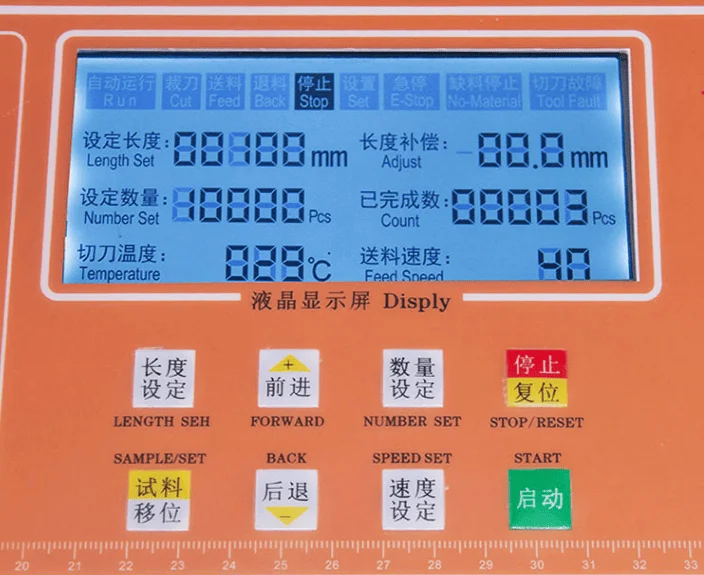

Key Machine Features

| Feature | Benefit |

|---|---|

| Programmable width | Create multiple ribbon sizes from one fabric roll |

| Hot knife cutting | Prevents fraying on synthetic fabrics |

| PLC control | Save multiple ribbon settings |

| Automatic feed & tension | Keeps fabric flat during cut |

Whether you need elastic ribbon, medical tape, or Velcro-style strips, our machines handle it—no sewing required.

Best Fabric Types for No-Sew Ribbons

| Fabric Type | Ideal for | Notes |

|---|---|---|

| Polyester | Packaging, tags | Melts cleanly with hot knife |

| Satin | Ceremonial, gifts | Needs careful sealing |

| Cotton | Rustic décor, crafts | Can be pinked or left raw |

| Organza | Wedding ribbon | Tear-prone, needs gentle handling |

| Linen | DIY and vintage style | Frays easily but looks aesthetic |

Dive Deeper: How to Make Torn Fabric Ribbon That Looks Beautiful—Not Sloppy

Torn ribbon can look elegant—but only if the tear is controlled.

To make torn fabric ribbon with a consistent look, always tear along the fabric grain and use tight-woven fabrics that fray evenly. For commercial use, machines can create torn-edge effects at scale.

Step-by-Step: DIY Torn Ribbon

-

Choose the right fabric

- Best: cotton, muslin, linen

- Avoid: knits, synthetics that melt

-

Pre-cut a small snip

- Use scissors to start a 1cm notch along the grain

-

Tear with steady pressure

- Pull slowly to keep edges straight

-

Optional: trim loose threads

- Use scissors or lightly singe the edge

-

Iron flat

- Wrinkles can make ribbon hard to work with

Creative Uses:

- Wedding bouquet wraps

- Vintage gift wrapping

- Rustic branding for handmade products

Torn Ribbon at Scale: Is It Possible?

Yes—factories like ours offer solutions.

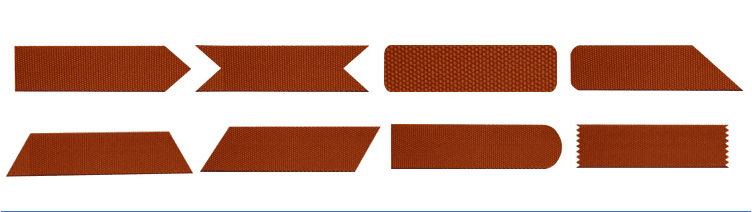

We’ve built custom rotary bevel cutting machines that simulate the torn-edge effect using special blades. This gives:

- Uneven but controlled edges

- Repeatable results

- No hand-tearing required

Some clients request this look for:

- Boutique product packaging

- Eco-friendly branding

- Limited-edition textile tags

If you’re a B2B buyer looking for this aesthetic in bulk, we can design a custom machine for your materials and widths.

Conclusion

Whether you want clean-cut or torn-edge ribbons from fabric—sewing isn’t required. The right cutting method and tools do the job better and faster.

Insights

To make ribbon from fabric without sewing, use sharp cutting tools and heat-sealing methods to prevent fraying. Suzhou Haoxinhe Electrical Equipment Co., Ltd. provides custom ribbon cutting machines that produce clean, consistent strips from fabric rolls—no stitching required. We also offer blade configurations that simulate torn edges for clients who want rustic or handmade aesthetics at industrial scale. These solutions reduce labor, speed up output, and preserve quality across ribbon applications from apparel to packaging.