How to stop ribbon fraying when you cut it?

Are you tired of seeing your production line stalled because batches of cut ribbon are unraveling before they even reach the assembly stage? For manufacturers working with synthetic webbing, satin, or nylon, fraying is not just a cosmetic annoyance; it is a structural failure that leads to high material waste and customer rejections.

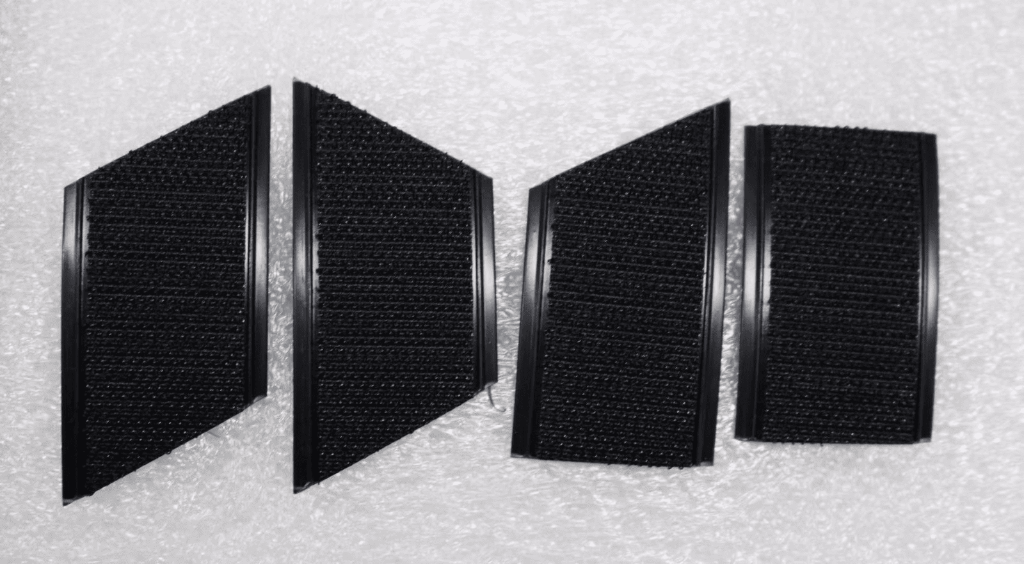

To stop ribbon from fraying when you cut it, you must apply a "thermal seal" simultaneously with the cut. While hobbyists might use lighters or fray-check glues, industrial production requires "Hot Knife Cutting." This process uses a heated blade to cauterize the cut ends of thermoplastic fibers, fusing them into a solid, fray-resistant bead instantly.

In this article, I will explain the science behind why ribbons fray, why manual "hacks" fail in a factory setting, and how to implement automated hot cutting solutions to ensure every single strap leaves your facility with a professional, permanent seal.

Why does ribbon fray in the first place?

Have you ever wondered why a piece of paper cuts cleanly, but a piece of ribbon explodes into loose threads? Understanding the structural difference between these materials is the first step to solving the fraying problem permanently.

Ribbon frays because it is a woven material held together by tension. When you use a cold blade (like scissors) to cut it, you sever the interlocking weave. Without the tension holding the warp and weft threads together, the cut edge loses its structural integrity, causing the loose fibers to unravel and fall apart.

The Physics of the "Cold Cut"

In my 12 years at HAOXINHE, I often explain to clients that "cutting" is actually "breaking." When you use a mechanical cold blade—whether it’s a pair of scissors, a rotary cutter, or a guillotine—you are applying shear force to break the fibers.

While this works for non-woven materials (like paper or felt) or natural fibers (like cotton) that don’t unravel easily, it is disastrous for synthetics.

- The Tension Release: A woven ribbon is like a grid of tension. Cut the grid, and the tension snaps back, pushing the threads out.

- The Friction Factor: As the product is handled, packed, or washed, friction pulls these loose threads further out.

If you are manufacturing pet leashes, garment labels, or tie-down straps, a "cold cut" is essentially a defective product. The only way to stop this physics chain reaction is to chemically or physically bond the ends together.

Is heat the only way to stop fraying?

Many small business owners ask me if they can use glues, chemical sealants, or even manual singing (using a lighter) to stop the fraying. While these methods exist, are they viable for a production environment?

While chemical sealants (fray check) or open flames can stop fraying temporarily, they are inconsistent and labor-intensive. Chemical glues take time to dry and can stain the fabric, while manual flame sealing results in uneven, blackened edges that look unprofessional and often fail quality control standards.

The Pitfalls of Manual Sealing Methods

Let’s break down why these "hacks" destroy your ROI (Return on Investment) in a manufacturing context.

-

Liquid Sealants / Glues:

- Process: You cut the ribbon cold, then apply a liquid adhesive to the tip.

- The Problem: It requires a drying rack, doubling your floor space usage. The glue often stiffens the edge too much, making it uncomfortable for skin contact (e.g., on lanyard ribbons). Furthermore, it is not permanent; washing can eventually dissolve the bond.

-

Manual Lighters / Handheld Torches:

- Process: An operator cuts the ribbon, then passes it through a flame.

- The Problem: Inconsistent heat. One second too long, and you have a black, charred lump. One second too short, and the seal is weak. This method relies entirely on the operator’s steady hand, which degrades over an 8-hour shift.

-

The Industrial Standard: Thermal Cutting

- This is why we advocate for Thermoplastic Fusion. Materials like Polypropylene (PP), Polyester (PET), and Nylon are thermoplastics. They melt when heated and re-harden when cooled. By using a blade that is both a cutter and a heater, you fuse the edge during the separation process. No secondary step is required.

Comparing the Methods

Here is a breakdown of how these methods stack up in a real-world production scenario:

| Method | Sealing Quality | Production Speed | Labor Cost | Edge Aesthetics |

|---|---|---|---|---|

| Scissors + Glue | Medium (Stiff edge) | Very Slow (Drying time) | High | Poor (Visible residue) |

| Scissors + Lighter | Low (Inconsistent) | Slow | High | Poor (Black/Burnt marks) |

| Automated Hot Knife | High (Smooth bead) | High (100+ pcs/min) | Low | Professional (Clean) |

How does automated hot cutting guarantee a perfect edge?

If manual heat is inconsistent, how does a machine solve the problem? The secret lies in the precise control of three variables: Temperature, Dwell Time, and Pressure.

Automated hot cutting machines stop fraying by strictly controlling the blade temperature to match the specific melting point of the material (e.g., 220°C for Polyester). The machine feeds the ribbon, pauses for a millisecond while the blade cuts and seals, and then advances, ensuring every single cut is identical and fully cauterized.

The Technology Inside the Cutopix Machines

At HAOXINHE, we design our Cutopix machines to eliminate the "human factor" from ribbon cutting. Here is how automation specifically addresses the fraying issue:

-

Material-Specific Temperature Control:

Different ribbons require different heat.- Satin: Needs a lower temperature/faster cut to avoid yellowing.

- Heavy Duty Nylon: Needs higher temperature to penetrate the thick weave.

- Our machines allow you to dial in the exact degree. If you use a handheld hot knife, the temperature fluctuates as you cut. An automated blade maintains thermal mass, ensuring the 1000th cut is as hot as the 1st.

-

Dwell Time (The "Kiss" of the Blade):

This is the most critical factor. If the blade stays on the ribbon too long, it melts too much plastic, creating a hard, sharp "burr" that scratches the skin. If it’s too short, it doesn’t seal. Automation creates a consistent "dwell time" (measured in milliseconds) that seals the edge without over-melting it. -

No Tension Stretching:

As mentioned earlier, tension causes fraying. Our machines use automatic feeding rollers that push the ribbon under the blade rather than pulling it. This relaxes the fabric right before the cut, ensuring the seal cures in a relaxed state. This is impossible to achieve by hand.

Case Study: The Backpack Manufacturer

We had a client manufacturing outdoor backpacks using nylon webbing. They were using guys with hot scissors. Their rejection rate was 15% due to "scratchy edges" complaining by customers. After switching to our automated hot cutter with a "Cold-Dwell" function (which cools the blade slightly after the cut), their rejection rate dropped to near zero, and they increased output by 400%.

Conclusion

To summarize, stopping ribbon fraying is not about finding better scissors; it is about changing the physics of the cut. For synthetic materials, Hot Knife Cutting is the only professional solution. It eliminates fraying by fusing the fibers at the molecular level. While manual methods exist, they cannot compete with the consistency, speed, and quality of an automated machine.

Call to Action (CTA)

Are you struggling with frayed edges or "scratchy" cuts on your current ribbon products? Don’t let poor cutting quality damage your brand reputation. Send your ribbon samples to HAOXINHE for a free test. We will configure our machines to your specific material, perform a test run, and send you the sealed samples (along with a video) so you can feel the smooth edge quality yourself. Email me at cherryhaoxinhesz@gmail.com to arrange your sample test today.