Manufacturing Pet Leashes: How to Cut Heavy Duty Nylon Without Scratching

The pet industry is booming, and customers are demanding higher quality. They want "Heavy Duty1" leashes that can hold a 50kg Rottweiler, but they also want "Soft Touch2" handles that don’t scratch their hands. This contradiction is the biggest challenge for manufacturers.

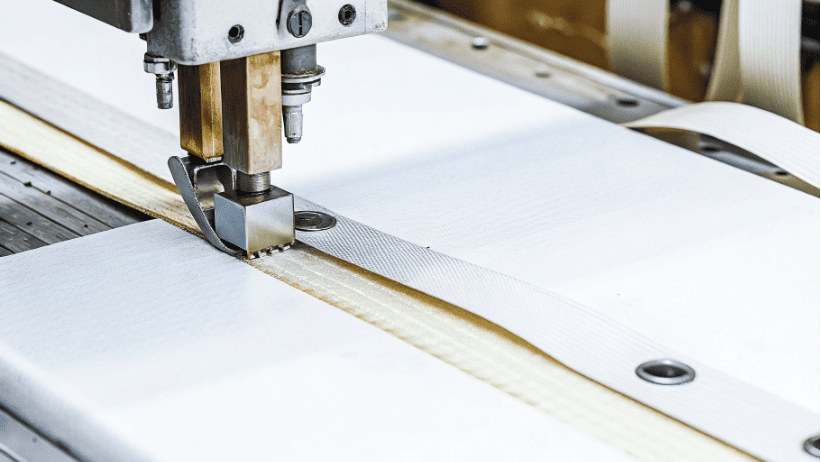

The best machine for manufacturing pet leashes and collars is a Hot Knife Cutter with "Blade Cooling" or "Ultrasonic" capabilities. While standard hot cutting seals the thick nylon to prevent unraveling, it often leaves a sharp, scratchy edge. Advanced machines use air-cooling or specialized molds to round off the cut, ensuring the product is pet-safe and consumer-friendly.

I am Cherry from HAOXINHE. I have helped pet brands move from garage production to factory scale. Here is how to cut thick nylon professionally.

How to Automate Pet Leash Production?

Pet leashes are usually made of thick Nylon or Polypropylene (2mm-4mm thick).

- Manual Cutting: Scissors are too slow. Handheld hot knives leave burnt, black blobs.

- The B2B Solution: You need a Heavy Duty1 Webbing Cutter (like our HX-200).

Addressing the "Scratchy Edge"

If a dog collar has a sharp melted edge, it will irritate the dog’s neck.

- Round Cut: Instead of a straight cut, use a Round Shape mold. A curved edge has no sharp corners to dig into skin.

- Ultrasonic Option: For premium "Soft Touch" leashes, Ultrasonic cutting creates a flush seal that feels like velvet. It is more expensive but allows you to charge a premium price.

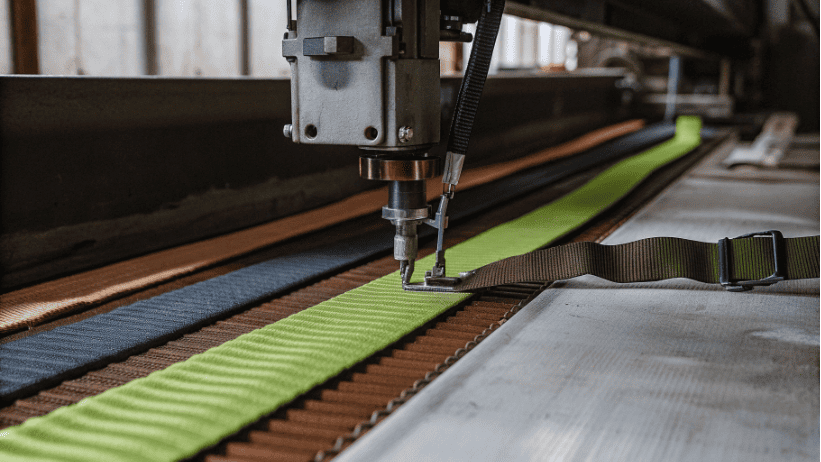

Deep Dive: Handling Multi-Layer Materials

Many modern leashes are "Padded." They have a layer of Nylon webbing sewn to a layer of Neoprene (foam).

Question: "Can I cut webbing and foam together?"

- The Challenge: Nylon needs 220°C to seal. Neoprene burns at 220°C.

- The Solution: You must use a Cold Guillotine Cutter3 for the combined material.

- Step 1: Cut the Nylon webbing on a Hot Knife machine (seal the ends).

- Step 2: Sew it to the Neoprene.

- Step 3: Cut the finished assembly on a Cold Cutter if needed, or cut the Neoprene separately on our Sheet Cutter.

[👉 INSERT LINK: Automatic Punching and Cutting Machine4]

Industrial / Manufacturing Considerations

Hole Punching for Buckles

Dog collars need holes for the tongue buckle.

- Inefficient Way: Cut strap -> Move to drill press -> Drill 5 holes.

- Efficient Way: Use our Automatic Punching and Cutting Machine4. It punches the 5 adjustment holes AND cuts the rounded tip in the same pass.

- Benefit: Perfect alignment. The holes are always centered.

Reflective Strip Issues

Many leashes have reflective threads (silver stripes) for night safety.

- Warning: These threads often contain metal or glass beads. They dull standard blades very quickly.

- Fix: Use Tungsten Carbide Blades or frequent sharpening cycles.

How Machines Solve This Problem

We configure machines specifically for the "Pet Sector."

- High Torque Motors: To pull heavy rolls of double-ply webbing.

- Reverse Function: If a thick buckle gets stuck (rare, but happens), the motor can reverse to clear the jam.

- Design Flexibility: Our machines can switch from cutting 1.5m Leashes to 40cm Collars in seconds by changing the program.

Conclusion

To summarize, in the pet industry, durability meets comfort. Your cutting machine must be powerful enough to cut thick nylon but precise enough to leave a smooth edge. Automating the "Cut & Punch" process is the fastest way to increase your margins.

🐾 Industry Insight: Lessons from Scaling 1,000,000+ Leashes

One thing I’ve learned from working with growing pet brands is this: the cut quality defines your brand reputation. Most customer complaints aren’t about the leash breaking—they’re about it feeling cheap or scratching their dog’s neck. The culprit? Poor heat sealing or misaligned hole punching.

A common mistake by first-time manufacturers is assuming one cutter fits all. But padded leashes with foam inserts behave completely differently during cutting than raw nylon webbing. That’s why modular machines with swappable dies and dual-mode cutting heads (hot/cold) give factories the flexibility to shift between SKUs without downtime.

Also, here’s an insider tip: retailers are asking for “ready to hang” collars—cut, punched, and branded. Machines that punch holes and cut the round tip in one pass not only save labor but ensure perfect consistency, which is key when scaling to global retailers.

-

Explore the advantages of Heavy Duty leashes for durability and safety, ensuring your pet’s comfort. ↩ ↩

-

Learn about Soft Touch technology that enhances comfort for both pets and owners, making walks enjoyable. ↩

-

Learn about Cold Guillotine Cutters and their role in cutting multi-layer materials without damage. ↩

-

Explore how this machine streamlines production by cutting and punching in one efficient process. ↩ ↩