Straight vs. Bevel (Angle) Cutting: Why the "Cut Angle" Matters for Assembly

If you manufacturing backpacks, pet leashes, or cargo straps, you know the struggle of the "Assembly Line Bottleneck1." Your sewing workers waste precious seconds trying to force a square-cut strap into a tight plastic buckle. The friction is high, the edges catch, and production slows down.

The difference between Straight Cutting and Bevel (Angle) Cutting is assembly efficiency. A Straight Cut (90°) is standard for sewing seams but difficult to thread into hardware. A Bevel Cut (usually 45° or trapezoid) creates a pointed end that slides easily into buckles and gliders. Achieving this requires a specialized Rotary Cutting Machine.

At HAOXINHE, we tell clients: "A straight cut saves material; a bevel cut saves labor." In this guide, I will explain when to invest in a rotary bevel cutting machine.

The "Buckle Problem2": Why Square Edges Fail

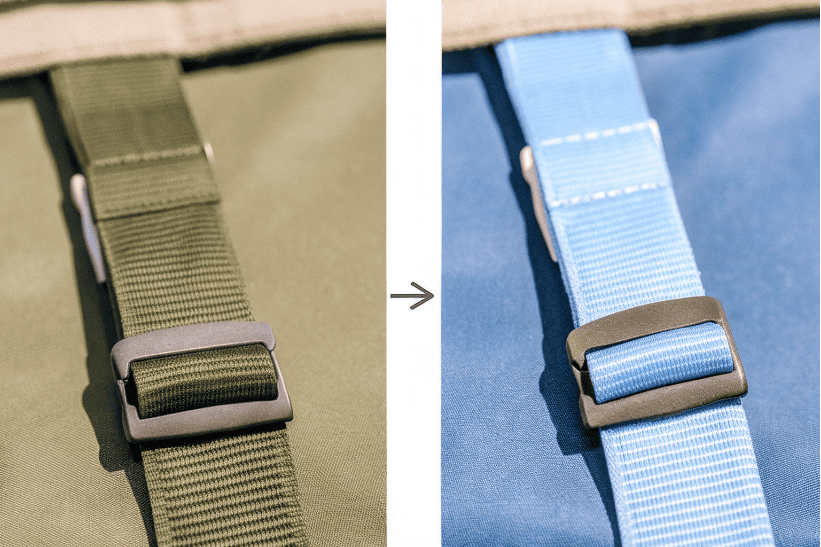

Imagine a 25mm wide strap going into a 25mm wide buckle.

- Straight Cut: The leading edge is exactly 25mm wide. You have to align it perfectly (0% margin of error) to get it in. If the edge is slightly frayed or the buckle is tight, it jams.

- Bevel Cut: If you cut the tip at a 45-degree angle, the leading edge becomes a point (maybe 2mm wide). It enters the buckle easily, and the worker simply pulls the rest through.

The Physics of the Angle Cut

Cutting at an angle is harder than cutting straight.

- Blade Length3: To cut a 50mm webbing at 45 degrees, the blade must travel approx. 70mm through the material.

- Heat Loss: A longer cut path means the blade contacts the material for longer, losing more heat. This often leads to "cold spots" in the middle of the cut if the machine is underpowered.

Available Methods: How to Cut Angles

You cannot cut angles efficiently with a standard straight cutter unless you build a complicated jig (which is unsafe). You need purpose-built technology.

1. Manual Rotation (The Wrong Way)

Operators twist the ribbon by hand under a straight hot knife.

- Result: Inconsistent angles. One strap is 40°, the next is 50°. It looks unprofessional.

2. Rotary Bevel Cutting Machine (The Right Way)

Our Rotary Bevel Series features a motorized blade head that rotates automatically between cuts.

- Programming: You can set it to cut:

/(slash),\(backslash),/ \(trapezoid), orV(arrow). - Precision: A stepper motor controls the blade rotation to 0.1-degree accuracy.

- Automation: It feeds, rotates, cuts, and seals in one continuous motion.

[👉 INSERT LINK: Rotary Bevel Cutting Machine]

Comparison Table

| Feature | Straight Cutter | Rotary Bevel Cutter |

|---|---|---|

| Blade Movement | Up/Down Only | Up/Down + Rotation |

| Speed | 100-120 cuts/min | 60-80 cuts/min |

| Assembly Speed | Slow (Hard to thread) | Fast (Easy threading) |

| Material Waste | Minimal | Higher (Triangular waste chips) |

| Machine Cost | $ | $$ |

Industrial / Manufacturing Considerations

If you are Mark, sourcing for a tactical gear factory, upgrading to Bevel Cutting is an ROI calculation.

Calculating the ROI

- Cost of Machine: A Rotary cutter costs more than a straight cutter.

- Labor Savings: If your assembly team saves 3 seconds per strap during threading, and you make 10,000 straps a day, that is 8.3 hours of labor saved daily. The machine pays for itself in weeks.

Challenges with Angle Sealing

As mentioned in our Nylon Cutting Guide, synthetic webbing needs heat to seal.

When cutting at an angle, the blade edge is effectively "duller" relative to the weave.

- Solution: We use specialized High-Mass Blades4 for our rotary machines. They hold more heat to compensate for the longer cut path, ensuring the tip of the bevel doesn’t fray.

How Machines Solve This Problem

The HAOXINHE Rotary Series is designed for versatility.

- Mode A: Fix the blade at 0° -> It acts as a high-speed straight cutter.

- Mode B: Set alternating angles -> It produces Trapezoids (ideal for bag straps).

- Mode C: Set parallel angles -> It produces Parallelograms.

We also integrate this with Automatic Hole Punching5. Imagine a strap that is cut at an angle and has a hole punched for a rivet instantly. That is what our automatic punching cutting machine can do.

Conclusion

To summarize, straight cutting is for sewing; bevel cutting is for assembly. If your product involves buckles, sliders, or hardware, a Rotary Bevel Cutting Machine is not a luxury—it is a necessity for efficient production flow.

Cherry’s Insights

Bevel (Angle) cutting is essential for manufacturing straps that need to be threaded into buckles, as the pointed tip significantly reduces assembly time compared to a square straight cut. While Straight Cutting is faster and wastes less material, it creates bottlenecks in downstream assembly. HAOXINHE recommends the Rotary Bevel Cutting Machine for factories producing pet leashes, tactical gear, and backpacks to automate precise angle cuts and heat sealing simultaneously.

-

Understanding bottlenecks can help improve production efficiency and reduce delays in manufacturing. ↩

-

Discover solutions to the buckle problem to enhance assembly efficiency and reduce labor costs. ↩

-

Understanding blade length can help optimize your cutting processes and improve overall production. ↩

-

Understanding high-mass blades can help you choose the right tools for efficient cutting and sealing. ↩

-

Learn about automatic hole punching to see how it can enhance your production efficiency and reduce manual labor. ↩