The Invisible Hazard: Managing Hot Knife Smoke in Production

Walk into a cutting room processing Nylon or PVC. If your eyes start to water and you smell burning plastic, that factory has a problem. Smoke and fumes are the inevitable byproduct of thermal cutting, but ignoring them is a business risk.

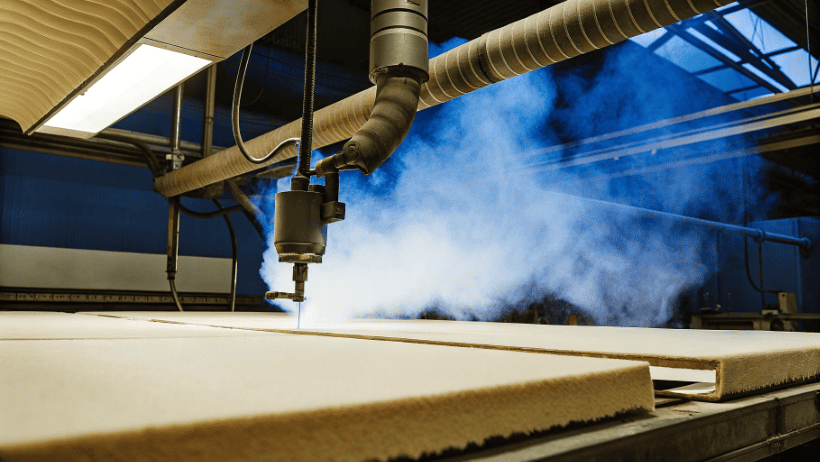

Hot Knife Cutting generates fumes containing Volatile Organic Compounds (VOCs) when melting synthetic fibers. To manage this, factories must implement "Source Capture" extraction systems. Installing exhaust fans directly at the cutting head removes smoke before it spreads, protecting worker health and preventing residue from staining the product.

I am Cherry from HAOXINHE. I have helped European clients meet strict EU air quality standards by retrofitting their cutting lines. Here is why smoke management is part of quality control.

Why Is the Smoke Bad? (Beyond the Smell)

- Health Risk: Melting Nylon releases Caprolactam. Melting PVC releases Hydrogen Chloride (acidic). Long-term exposure is harmful to operators.

- Quality Risk (Yellowing): smoke is just carbon particles suspended in air. If it isn’t removed, it settles back down onto your pristine white ribbon, causing grey/yellow stains.

- Machine Corrosion: Acidic fumes (from PVC or heavy plastics) corrode the metal parts of your machine, destroying sensors and bearings over time.

Deep Dive: Extraction Solutions

Opening a window is not enough. You need directed airflow.

1. The "Elephant Trunk" (Local Exhaust)

This is a flexible duct arm positioned 10cm from the blade.

- Pros: Cheap, easy to install.

- Cons: If positioned poorly, it pulls the ribbon off the track or cools the blade down too much (creating cold spots).

2. Integrated Chassis Extraction (The HAOXINHE Way)

On our industrial webbing tape cutting machine, we build the extraction ports into the blade guard.

- Design: A slotted vent sits directly behind the blade.

- Efficiency: It catches the smoke the micro-second it is generated.

- Fan: A high-static pressure fan forces the smoke through a filter or out of the building.

3. Air Scrubbers (Recirculation)

If you cannot vent outside (e.g., rented warehouse), you need a Carbon Filter Unit. It sucks the smoke, scrubs the VOCs with activated charcoal, and returns clean air to the room.

👉 INSERT LINK: Hot and Cold Cutting Machine Series

Industrial / Manufacturing Considerations

Blade Temperature vs. Airflow

There is a tricky balance.

- Too much suction: The airflow cools the hot blade. The controller fights to heat it up, burning out the heater cartridge.

- Solution: We use Variable Speed Fans. You tune the suction to be just enough to catch the wisps of smoke, but not enough to create a wind tunnel.

Material Toxicity

Know what you are cutting.

- Polyester/Nylon: Smoke is annoying but manageable.

- PVC/Vinyl: Smoke is corrosive and toxic. You MUST use stainless steel extraction hoods (plastic hoods will melt or corrode) and vent outside.

How Machines Solve This Problem

At HAOXINHE, we treat the machine environment as a system.

- Enclosed Guards: We use clear acrylic guards around the cutting zone. This not only protects fingers but contains the smoke so the extractor can grab it efficiently.

- Air Assist: For our Laser Cutting alternatives, we use compressed air to blow smoke through the material into a downdraft table, keeping the top surface clean.

Even for our wire cutting and stripping machine (which burns insulation), fume extraction is a standard option.

Conclusion

To summarize, smoke is waste. It’s waste material in the air. Managing it is not just about being "green"; it’s about keeping your white ribbons white and your staff working efficiently. Don’t let your factory become a gas chamber.

🧠 Cherry’s Industry Insight: Why Source Capture Isn’t Optional—It’s Critical

In over 20 years of factory visits and retrofits across Europe and Asia, one pattern keeps repeating: production managers often treat smoke as an afterthought—until it causes visible damage or a labor complaint. What they don’t realize is that by the time the smoke is visible, it’s already compromising product quality and equipment lifespan.

The smartest factories treat hot knife smoke the same way semiconductor fabs treat dust: as a contamination issue, not just a comfort one. Think of smoke like "invisible lint" that clings to white nylon ribbons or Kevlar belts. If your customer is in automotive or aerospace, even minor discoloration could lead to rejection or recalls.

Also, too many teams rely on general ventilation (ceiling fans, wall vents). But VOC particles cool and settle fast, often within seconds. That’s why I always push for source capture at the blade. It’s not just an upgrade—it’s a first-line defense.