What Do You Need for Ribbon Cutting?

Trying to cut ribbon with regular scissors often leads to frayed edges, uneven lengths, and wasted materials.

To cut ribbon effectively, you need the right cutting tool—preferably a hot knife ribbon cutting machine—and a stable setup that ensures consistent tension and clean edges.

Many businesses overlook how important the cutting process is. Whether you’re preparing packaging, labels, or textile trims, poor cuts impact appearance and performance. Here’s what you really need to make clean, efficient cuts—every time.

How Do You Cut Ribbon Without It Fraying?

Frayed ribbon not only looks messy, it unravels over time—damaging product quality and customer trust.

The best way to cut ribbon without fraying is by using a hot knife cutter. This method cuts and seals the ribbon edge simultaneously, preventing the fibers from unraveling.

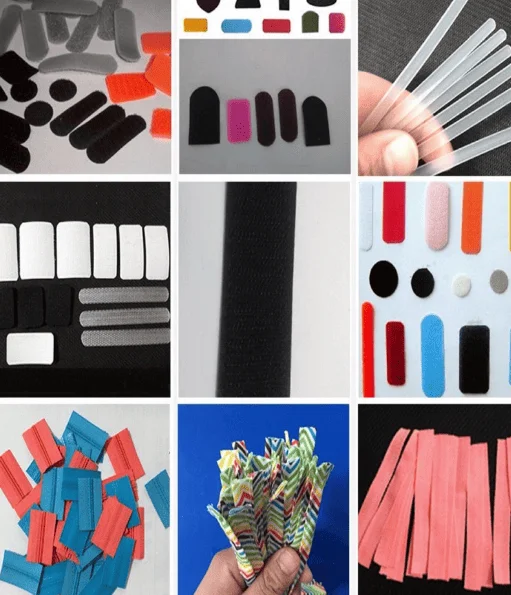

This is especially important for synthetic materials like nylon, polyester, and satin. These fibers fray easily when cut cold. But when heat is applied at the moment of cutting, the fibers melt slightly and bond at the edge, locking everything in place.

Why Hot Knife Cutting Prevents Fraying

Unlike scissors or rotary cutters, a hot knife cutter does two jobs at once:

- Cuts the ribbon cleanly

- Applies heat to seal the edge

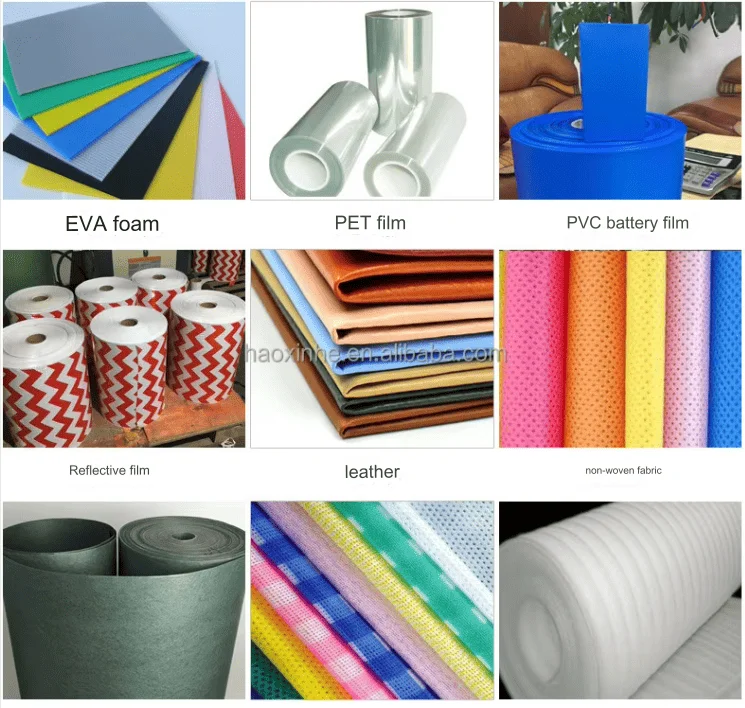

Machines from Suzhou Haoxinhe Electrical Equipment Co., Ltd., like our hot and cold cutting machine and webbing ribbon cutting machine, are equipped with high-precision temperature control. This means you get a sealed edge without burning or discoloration.

Fraying Risk by Ribbon Type

| Ribbon Type | Fraying Risk | Best Cutting Method |

|---|---|---|

| Satin | High | Hot knife cutter |

| Grosgrain | Medium | Cold cutter with sharp blade |

| Organza | High | Low-heat cutter |

| Elastic | High | Cold blade + speed control |

| Nylon Webbing | Very High | Hot knife with temperature control |

| Cotton Ribbon | Low | Rotary cutter |

If you’re still relying on scissors, the risk of fraying is guaranteed. Using our machines, especially the automatic punching cutting machine or the rotary bevel cutting machine, eliminates that issue entirely.

Bonus: Clean Cuts Improve Productivity

When ribbon doesn’t fray, you skip:

- Manual edge trimming

- Rework or replacements

- Customer complaints about quality

And instead, you get:

- Faster processing

- Cleaner product presentation

- Lower material waste

Dive Deeper: What Equipment Do You Actually Need for Ribbon Cutting?

Not all cutting setups are equal. Choosing the right one depends on your production scale, ribbon materials, and end-use requirements.

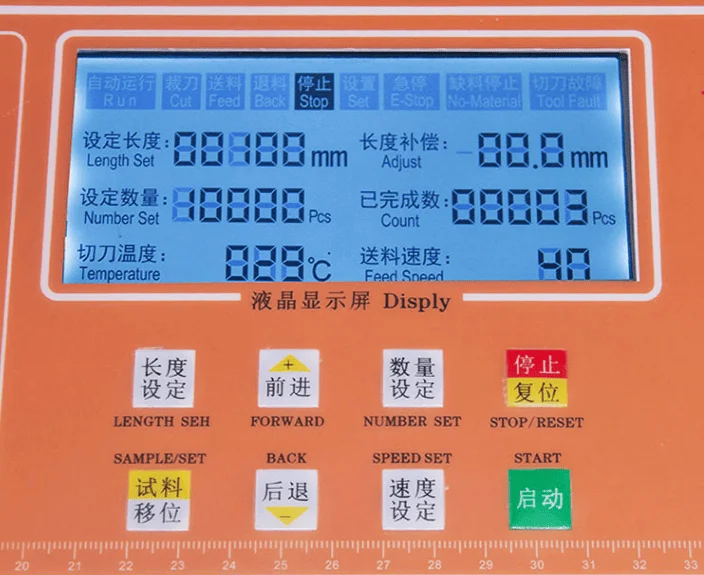

At minimum, you need a sharp blade, stable tension, and accurate measurement. For industrial use, you need a programmable ribbon cutting machine with heat-sealing and auto-feed features.

Let’s walk through the three tiers of ribbon cutting setups:

1. Manual Setup – Low Budget, Low Volume

This setup is for small-scale or hobby use.

- Tools: Fabric scissors or rotary cutter

- Limitations: Inconsistent lengths, fraying edges, slow processing

- Applications: DIY crafts, small gift shops

If you cut less than 10 meters per day, this may be enough.

2. Semi-Automatic Setup – Moderate Volume

This is a step up for small businesses.

- Tools: Handheld hot knife or tabletop cutter

- Improvements: Heat sealing, straighter cuts

- Limitations: Manual feeding, human error in length

Useful for custom garment tags or small packaging runs.

3. Industrial Automatic Setup – High Volume, High Precision

This is where Suzhou Haoxinhe comes in.

- Tools:

- Webbing ribbon cutting machine

- Hot and cold cutting machine

- Computer tube cutting machine

- Automatic punching cutting machine

- Advantages:

- Programmable length

- Adjustable feed speed

- Hot/cold blade switching

- Fray-free edge sealing

- Industries Served:

- Packaging

- Automotive (seatbelts, straps)

- Medical tapes

- Textile & Apparel

- Electronics & labeling

Which One Fits You?

| Production Volume | Suggested Equipment | Key Benefit |

|---|---|---|

| <10m/day | Scissors or rotary cutter | Budget friendly |

| 10–100m/day | Handheld hot knife | Cleaner edge |

| 100–1000m/day | Semi-auto ribbon cutter | Time-saving, consistent lengths |

| 1000m+/day | Haoxinhe automatic ribbon cutting machine | Maximum speed and precision |

When our B2B clients from Canada, Singapore, or Germany contact us, they’re often upgrading from semi-automatic tools. We provide them with tailored machines like the round shape cutting machine or the protective foam cutting machine, depending on their ribbon type.

We also help them reduce waste, save labor, and improve quality—without hiring more staff or slowing down production.

Conclusion

To cut ribbon smoothly and prevent fraying, you need the right machine—with heat, precision, and speed. Manual tools just can’t keep up.

Insights

To cut ribbon without fraying, the best solution is a hot knife ribbon cutting machine that seals edges while slicing. Suzhou Haoxinhe Electrical Equipment Co., Ltd. offers a range of industrial ribbon cutting machines that support hot and cold cutting, programmable lengths, and adjustable speeds. These machines are perfect for packaging, textile, automotive, and medical industries needing clean, efficient ribbon cuts. Upgrading to a professional cutting solution reduces waste, improves quality, and saves time.