What is another name for ribbon cutting?

Are you confused by the different terms used for cutting industrial fabrics and wondering which process is right for your production line? In the manufacturing world, using the wrong terminology can lead to purchasing equipment that fails to meet your specific edge-sealing requirements.

In the textile and manufacturing industry, "ribbon cutting" is technically referred to as "Hot Knife Cutting," "Thermal Cutting," or "Automatic Webbing Cutting." These terms specifically describe the process of using a heated blade to sever synthetic materials like satin, nylon, or polyester while simultaneously sealing the edges to prevent fraying.

In this article, I will share the specific industrial terms we use at HAOXINHE and explain the technical differences between them. I will also guide you through the most common production headache—fraying edges—and how to solve it using the correct automated technology.

Cutting Ribbon without the Frays?

Does your production line suffer from high rejection rates because your cut ribbons have loose threads or rough, burnt edges? Fraying is the most common issue when processing woven synthetic materials, and it usually happens because the cutting method does not match the material properties.

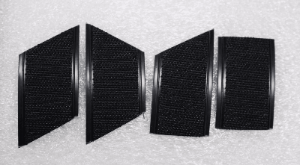

To cut ribbon without frays, you must use a "Hot Knife" or "Thermal Sealing" process rather than a cold mechanical cut. The heated blade melts the synthetic fibers (such as polyester or nylon) at the precise cut point, fusing the strands together to create a smooth, sealed, and burr-free edge that will not unravel.

The Science Behind Fraying and Sealing

To understand how to eliminate frays, we first need to look at the material structure. Most industrial ribbons, webbing, and hook-and-loop fasteners (Velcro) are woven structures made from synthetic fibers. When you use standard scissors or a "cold blade" guillotine cutter, you are mechanically breaking these woven strands. Once the tension is released, the weave structure loosens, and the individual threads begin to fall out. This is what we call fraying.

In my 12 years of experience at HAOXINHE, I have seen many factory managers try to solve this by applying glue or post-processing the edges manually. This adds huge labor costs and slows down production.

The correct engineering solution is Thermal Cutting.

Synthetic materials have a specific melting point. A high-quality automatic ribbon cutting machine uses a conductive metal blade heated to a specific temperature (usually between 180°C and 300°C, depending on the thickness). As the blade passes through the material, it does two things simultaneously:

- Separation: It cuts the material to the specified length.

- Sealing: It melts the cross-section of the fibers, fusing them into a solid bead.

Manual vs. Automated Hot Cutting

You might be using a handheld hot knife right now. While this stops fraying, it relies heavily on the operator’s skill. If the operator moves too slowly, the material burns or creates a hard, blackened edge. If they move too fast, the seal is incomplete.

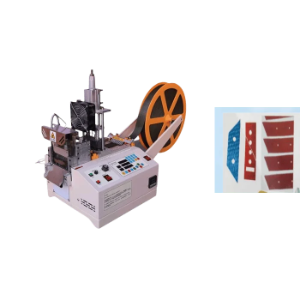

An automated machine, like our Cutopix series, controls three critical variables that a human cannot perfectly replicate:

- Temperature Consistency: Sensors ensure the blade stays at the exact set temperature.

- Dwell Time: The time the blade touches the material is calculated in milliseconds.

- Pressure: The cutting force is uniform for every single cut.

Comparison of Cutting Methods

Here is a breakdown of why shifting to an automated hot knife system is essential for quality control.

| Feature | Cold Cutting (Scissors/Guillotine) | Handheld Hot Knife | Automated Hot Knife Machine (Cutopix) |

|---|---|---|---|

| Edge Quality | High risk of fraying | Sealed but inconsistent | Perfectly sealed, uniform edge |

| Speed | Slow | Very Slow | High Speed (100+ cuts/minute) |

| Length Accuracy | Low (Human error) | Low (Human error) | High Precision (±0.1mm) |

| Labor Cost | High | High | Low (One operator manages multiple machines) |

| Material Waste | High | Medium | Low |

Choosing the Right Machine for Your Material

Not all "ribbon cutting" machines are the same. At HAOXINHE, we often ask clients to send us their material first because different materials require different blade shapes and heating capacities.

For example, if you are cutting satin ribbon for gift packaging, you need a thin, sharp heated blade to ensure the edge is soft and not scratchy. However, if you are cutting heavy-duty nylon webbing for cargo straps, you need a thick, wedge-shaped blade that provides enough heat energy to seal the thick fibers deeply.

We also encounter elastic ribbons. Cutting elastic is tricky because if you stretch it while cutting, the length will be wrong when it snaps back. Our machines utilize specific feeding rollers and tension-control sensors to feed the elastic through the hot knife without stretching it, ensuring the final length is exactly what you programmed.

By understanding that "ribbon cutting" in an industrial context really means "precision thermal sealing," you can stop looking for generic scissors and start looking for the specific automation technology that solves the fraying problem at the source.

Conclusion

To summarize, while many people say "ribbon cutting," the industrial term you should use is Hot Knife Cutting or Thermal Sealing. The only way to permanently prevent fraying on synthetic woven materials is to use heat to fuse the edges during the cutting process, and automating this ensures consistency and speed.

Call to Action (CTA)

Are you struggling with frayed edges or inconsistent lengths in your current production? Don’t guess which machine is right for you. Send us your material samples for a free test cut. Our engineering team at HAOXINHE will test your specific ribbon or webbing on our machines, record a video of the process, and send the samples back to you so you can inspect the edge quality yourself. Contact us today at cherryhaoxinhesz@gmail.com or visit our website to start optimizing your cutting process.