What supplies do I need for a ribbon cutting?

Many people think a ribbon cutting only needs ribbon and scissors, but this assumption causes problems once consistency, appearance, and efficiency matter. Uneven cuts, frayed edges, and slow preparation quickly appear. The right equipment turns ribbon cutting into a controlled, repeatable process.

For a professional ribbon cutting—especially when preparing ribbons in advance—the essential supplies include the right ribbon material, a ribbon cutting machine, and basic handling accessories to ensure clean, consistent, and efficient cuts.

In this article, I will share what supplies are truly required for ribbon cutting from a production and preparation perspective, and explain why a ribbon cutting machine is a better solution than manual tools.

What do you need for ribbon cutting?

When ribbon cutting is repeated, prepared in batches, or requires uniform length and clean edges, the supply list changes completely.

You need suitable ribbon material, a ribbon cutting machine matched to the ribbon type, and basic handling accessories to keep ribbon clean and organized. Manual scissors are only suitable for very small, one-time ceremonial use.

Below, I explain each supply using a problem-versus-solution approach based on real manufacturing and preparation scenarios.

Ribbon material: what works best with a machine?

Ribbon quality directly affects cutting results, especially when machines are used.

Problem:

Low-quality or inconsistent ribbon thickness leads to unstable feeding, length deviation, and uneven edges during cutting.

Solution:

Use uniform, production-grade ribbon designed for machine feeding.

Recommended ribbon specifications:

- Material: Polyester, satin, or woven ribbon with stable thickness

- Width: Defined and consistent across the roll

- Structure: No loose fibers or excessive elasticity

| Ribbon Type | Feeding Stability | Cut Edge Quality | Machine Compatibility |

|---|---|---|---|

| Thin craft ribbon | Low | Unstable | Poor |

| Satin ribbon | High | Clean | Excellent |

| Polyester ribbon | Very high | Very clean | Excellent |

From my experience, consistent ribbon structure is more important than decorative appearance when machine cutting is involved.

Ribbon cutting machine: why it replaces scissors?

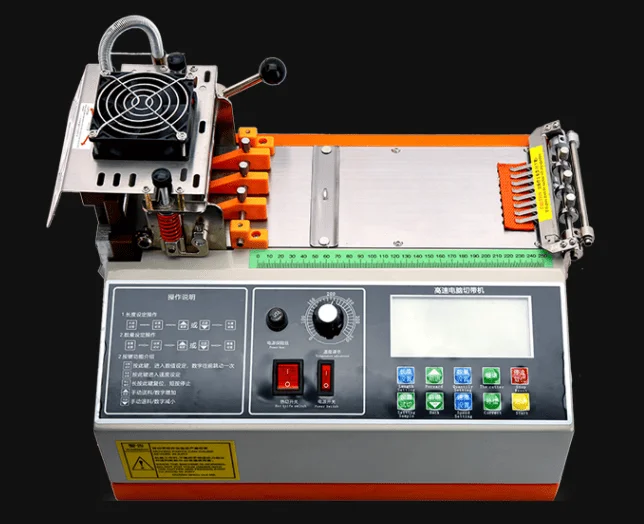

The core supply for modern ribbon cutting is the ribbon cutting machine itself.

Problem:

Manual cutting with scissors cannot control length tolerance1, edge quality, or output speed2. Results depend entirely on the operator.

Solution:

A ribbon cutting machine feeds, measures, and cuts ribbon automatically, delivering consistent results every cycle.

Typical technical benefits include:

- Length tolerance within ±0.5–1 mm

- Cutting speeds up to 100–120 pcs/min (based on short lengths)

- Stable feeding for soft or slippery ribbon

- Optional hot cutting for sealed, burr-free edges

| Aspect | Manual Scissors | Ribbon Cutting Machine |

|---|---|---|

| Length accuracy | Unstable | Controlled |

| Edge consistency | Variable | Stable |

| Output speed | Low | High |

| Labor dependence | High | Low |

| Repeatability | Poor | Excellent |

In real use, machines allow ribbon to be prepared in advance, packed neatly, and used during ceremonies without any cutting on-site.

Hot cutting vs cold cutting: which machine function is needed?

Not all ribbons behave the same during cutting.

Problem:

Cold cutting leaves frayed edges on synthetic ribbon. Hot cutting damages natural fibers if not controlled.

Solution:

Choose a ribbon cutting machine with the correct cutting method.

| Ribbon Material | Recommended Method | Result |

|---|---|---|

| Polyester / Satin | Hot cutting | Sealed, no fraying |

| Nylon ribbon | Hot cutting | Clean edge |

| Cotton ribbon | Cold cutting | No scorching |

From a technical standpoint, matching cutting method to ribbon material is critical for edge quality and appearance.

Handling and organization supplies: what supports machine cutting?

Machine cutting improves efficiency, but handling still matters.

Problem:

Cut ribbons become tangled or contaminated after cutting.

Solution:

Prepare basic handling supplies to support machine output.

Useful items include:

- Collection trays or bins

- Length-sorted packaging bags

- Labels for quantity and length identification

These supplies keep cut ribbon organized and ready for use without rework.

Why machines matter even for ceremonial ribbon cutting3?

Even when the final event is symbolic, preparation quality matters.

Problem:

On-site cutting introduces uncertainty, delays, and uneven results.

Solution:

Prepare ribbon in advance using a ribbon cutting machine, ensuring every piece is identical.

From an operational view, machine preparation removes last-minute risk. The ceremony becomes a presentation, not a cutting task. Consistency is guaranteed before the event starts.

Conclusion

Ribbon cutting is no longer just about scissors and ribbon. The right ribbon material and a suitable ribbon cutting machine ensure clean edges, accurate length, and efficient preparation. Machines turn ribbon cutting into a predictable, controllable process.

Insights

From my experience in automated cutting equipment, ribbon cutting quality is determined long before the ceremony. Length accuracy, edge condition, and ribbon consistency all come from machine preparation. When ribbon is cut by machine, the event runs smoothly. When it is cut by hand, variability is unavoidable. Reliable results always come from controlled processes, not manual tools.