Cutting Polypropylene (PP) Webbing: Mastering the Low-Melting Point Challenge

Polypropylene (PP) is the budget king of the webbing world. It is lightweight, water-resistant, and cheap. You see it on grocery tote bags, disposable medical straps, and light-duty backpacks. However, cutting it cleanly is surprisingly difficult because it melts too easily.

To cut Polypropylene (PP) webbing effectively, you must use a Hot Knife at a lower temperature setting (around 160°C – 180°C) compared to Polyester or Nylon. PP has a low melting point and low viscosity; if the blade is too hot, the edge turns into a messy, stringy "plastic goo" that sticks to the blade and deforms the strap.

I am Cherry from HAOXINHE. Many clients send me samples of PP webbing saying "My machine is broken, the cuts are ugly." The machine is fine; the temperature is just too high. Here is how to fix it.

Why PP Behaves Differently than Nylon

In our Polyester Guide, we talked about how polyester needs ~250°C to melt.

- Nylon: Melts ~220°C. Becomes sticky but manageable.

- PP: Melts ~160°C. Becomes liquid almost instantly.

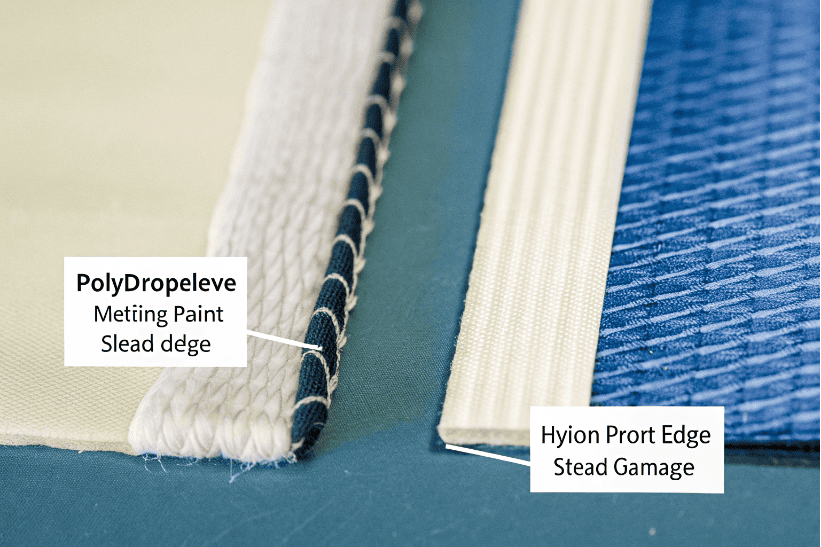

The "Stringing" Phenomenon

When a hot blade lifts off molten PP, the plastic stretches like hot cheese on a pizza. These thin strands (angel hair) cool down and look like spiderwebs on the edge of your strap.

- The Cause: Blade is too hot OR dwell time is too long.

- The Result: Messy edges that require manual trimming (waste of money).

Deep Dive: The Low-Temp Strategy

To cut PP professionally, you need a machine with PWM (Pulse Width Modulation)1 or precise temperature control. An "On/Off" switch is not good enough.

1. Temperature Control

Set your webbing tape cutting machine2 to the lowest setting that still cuts.

- Start low: 150°C.

- Test: If it doesn’t cut through, increase by 5°C.

- Goal: You want to sever the fibers, not boil them.

2. Blade Speed

For PP, speed is your friend.

- Fast Action: A quick chop minimizes heat transfer.

- Cold Dwell: Unlike Nylon which needs time to seal, PP seals instantly. Get the blade out of there quickly to prevent "stringing."

👉 INSERT LINK: Automatic [Hot Knife](https://www.youtube.com/watch?v=eX78zZzspH0)3 Cutting Machine

Industrial / Manufacturing Considerations

PP is often used for high-volume, low-cost items (e.g., promotional bags). Margins are thin. You cannot afford rejection.

The Blade Coating Factor

Because PP is so sticky when melted, it fouls blades quickly.

- Maintenance: Operators must clean the blade much more frequently than with Polyester. We recommend a quick wipe with a brass brush every 2 hours.

- Teflon Coating4: HAOXINHE offers coated blades specifically for Protective Foam Cutting Machine5 and PP applications to reduce adhesion.

Fumes

PP smoke is generally less toxic than PVC or Nylon, but it smells like burning wax. In a factory with 20 machines running PP, the smell can be overwhelming. Ventilation is still required.

How Machines Solve This Problem

We calibrate our machines differently for PP clients.

- Cooling Fans: Some of our hot and cold cutting machine models feature a small air nozzle directed at the blade path. This blasts cool air immediately after the cut, freezing the PP edge before it can string out.

- Blade Geometry: We use a thinner blade for PP. A thick wedge blade (used for Heavy Nylon) retains too much heat and causes over-melting on thin PP tapes.

For very light PP (like non-woven shopping bags), we might even recommend Ultrasonic Cutting6 or Cold Cutting with a heated press, as these methods generate less radiant heat.

Conclusion

To summarize, PP is sensitive. It requires finesse, not brute force. Turn your temperature down, increase your cutting speed, and keep your blades clean. With the right settings, PP can have a smooth, professional edge just like expensive Nylon.

Cherry’s Insights for Google Snippet

Polypropylene (PP) webbing requires a lower cutting temperature (160°C-180°C) than Polyester or Nylon to prevent over-melting and "stringing." Because PP turns into a low-viscosity liquid quickly, using a high-speed Hot Knife with precise temperature control is crucial. HAOXINHE recommends using thin blades and frequent cleaning cycles to prevent the melted plastic from accumulating and ruining the edge finish.

-

Learn how PWM technology enhances precision in cutting polypropylene webbing. ↩

-

Discover the essential features of cutting machines designed specifically for polypropylene. ↩

-

Explore how a Hot Knife can effectively cut polypropylene webbing without causing damage. ↩

-

Find out how Teflon coatings can reduce adhesion and improve cutting efficiency. ↩

-

Discover how specialized machines can enhance cutting performance for polypropylene. ↩

-

Explore the benefits of Ultrasonic Cutting for delicate polypropylene applications. ↩