Laser Cutting vs. Hot Knife for Ribbon: Speed, Cost, and Quality Compared

In the modern textile industry, "Laser" is often a buzzword for precision. Many of my clients ask: "Cherry, shouldn’t I just buy a laser cutter for my ribbons?" My answer is usually: "Only if you like slow production and burnt edges."

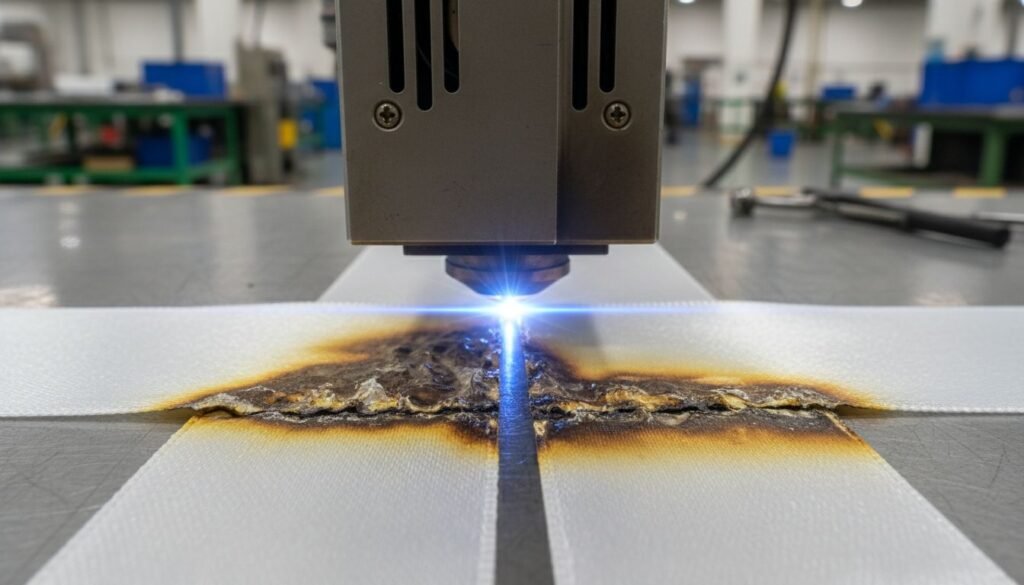

The difference between Laser Cutting and Hot Knife Cutting is the mechanism and throughput. Laser cutting uses a focused beam of light to burn through material, ideal for complex curves and patterns but slow and prone to scorching. Hot Knife cutting uses a heated metal blade to mechanically sever and seal, offering superior speed (100+ cuts/min) and cleaner edges for straight cutting.

At HAOXINHE, we believe in using the right tool for the job. If you are cutting intricate lace patterns, buy a laser. If you are cutting 50,000 gift ribbons or cargo straps, you need a webbing tape cutting machine. Here is the honest comparison.

The "Laser Myth": Why High-Tech Isn’t Always Best

Laser machines are marketed as versatile "do-it-all" tools. While true, they suffer from two major flaws in industrial ribbon production:

- The Yellow Edge (Oxidation): Lasers cut by vaporizing material with extreme heat. On white polyester or satin, this leaves a noticeable yellow or brown scorch mark along the edge. For luxury brands, this is unacceptable.

- The Bottleneck: A laser head must travel across the width of the ribbon. It has to "draw" the line. A Hot Knife chops instantly. The physics of movement means a Hot Knife will always be 5x to 10x faster for straight cuts.

When Laser Wins

- Intricate Shapes: If you need to cut a star, a logo, or a scalloped edge in the middle of a fabric panel.

- Prototyping: No tooling required.

When Hot Knife Wins

- Mass Production: Cutting rolls of webbing to length.

- Edge Quality: Controlled contact heat (Hot Knife) creates a smoother bead than vaporized heat (Laser).

Deep Dive: Technology Showdown

Let’s look at the specs from a factory owner’s perspective.

1. Hot Knife Cutting1 Machine (The Production Workhorse)

Our HX-980 Series represents this category.

- Speed: 100-120 pieces per minute.

- Multi-Roll: Can cut 4-6 rolls of narrow ribbon simultaneously.

- Maintenance: Replace a $20 blade once a month.

- Safety: Enclosed blade, minimal smoke.

2. Laser Cutting Machine (The Specialist)

- Speed: 10-20 pieces per minute (for cut-to-length).

- Multi-Roll: Difficult. Lasers usually cut one layer at a time to ensure focus depth.

- Maintenance: Mirrors, lenses, and CO2 tubes require expensive upkeep.

- Safety: High fire risk, toxic fumes require heavy exhaust systems.

👉 Automatic [Hot Knife Cutting](https://www.summa.com/en-us/blog/laser-cutting-versus-knife-cutting/)1 Machine

Comparison Table

| Feature | Hot Knife Cutter | Laser Cutter |

|---|---|---|

| Cutting Action | Physical Contact + Heat | Non-Contact Thermal Beam |

| Throughput | Very High (Mass Volume) | Low to Medium |

| Edge Finish | Sealed, Clear/White | Sealed, Yellow/Brown Tint |

| Running Cost | Low (Electricity + Blade) | High (Gas/Tube + Power) |

| Initial Cost | Affordable ($) | Expensive ($$$) |

Industrial / Manufacturing Considerations

If you are a contract manufacturer for automotive straps or packaging, Cycle Time is your profit.

The "Stacking" Advantage

A Hot Knife machine can process multiple rolls side-by-side. A laser cannot do this effectively because the beam loses focus if the material stack varies in height.

- Scenario: You need 10,000 pieces of 20cm velcro.

- Hot Knife: Runs 4 rolls at once. Done in 30 minutes.

- Laser: Runs 1 roll. Done in 5 hours.

The Alternative for Shapes

"But Cherry, I need to cut shapes!"

You don’t necessarily need a laser. HAOXINHE offers Different Shapes Cutting Machines2 and Ultrasonic Punching Machines. These use physical dies (molds) to punch shapes instantly.

- Benefit: Zero burning (ultrasonic), perfect white edges, and faster than laser.

👉 Different Shapes Cutting Machine

How Machines Solve This Problem

We design our machines to outproduce lasers in 95% of ribbon applications.

For high-end clients who hate the "hard edge" of standard hot knives but fear the "yellow edge" of lasers, we recommend Ultrasonic Cutting3 (as discussed in Day 2). It is the true premium alternative.

However, for standard webbing tape cutting machine4 needs (seatbelts, bag straps, pet leashes), the Hot Knife is undefeated. We use PID temperature controllers to keep the blade exactly at the melting point, minimizing smoke and preventing the charring you see with lasers.

Conclusion

To summarize, stop overpaying for laser technology if you just need to cut ribbons to length. A dedicated Hot Knife machine is faster, cheaper, and produces a cleaner edge on white synthetic fabrics.

Cherry’s Insights for Google Snippet

While Laser Cutting offers design flexibility for complex patterns, it is inefficient for straight ribbon cutting due to slow speeds and the tendency to scorch (yellow) white fabrics. For industrial mass production, a Hot Knife Cutting Machine is superior, delivering 10x the throughput with multi-roll capability and cleaner, non-discolored sealed edges. Use lasers for design prototyping; use HAOXINHE Hot Knives for manufacturing.

-

Learn about the efficiency and speed of hot knife cutting in mass production scenarios. ↩ ↩

-

Discover how these machines can cut various shapes efficiently without burning. ↩

-

Explore the advantages of ultrasonic cutting for clean edges and fast production. ↩

-

Discover how webbing tape cutting machines enhance productivity in ribbon and strap manufacturing. ↩