Precision Cutting for Medical Tubing: Zero Contamination, Zero Deformation

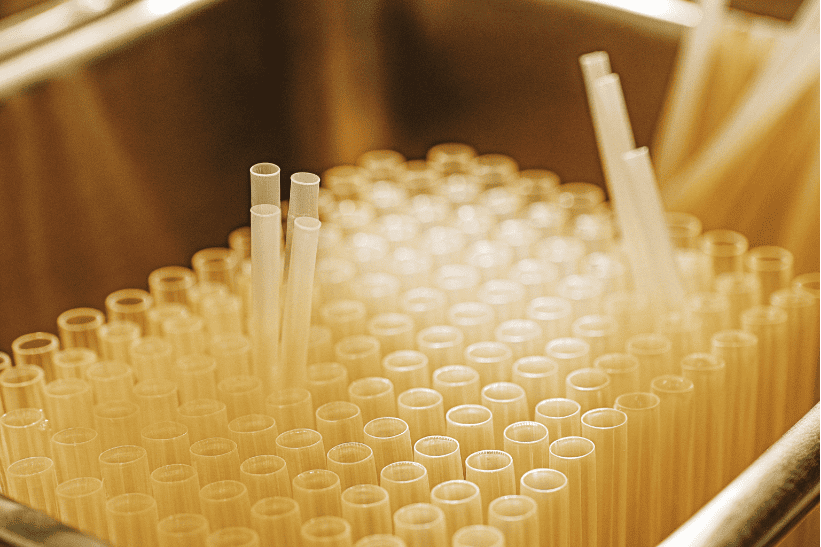

Cutting medical tubing (for IV sets, catheters, or peristaltic pumps) is not just about length—it’s about hygiene and geometry. A crushed tube effects flow rate. A jagged cut causes leaks. Standard industrial cutters are often too "rough" for this sector.

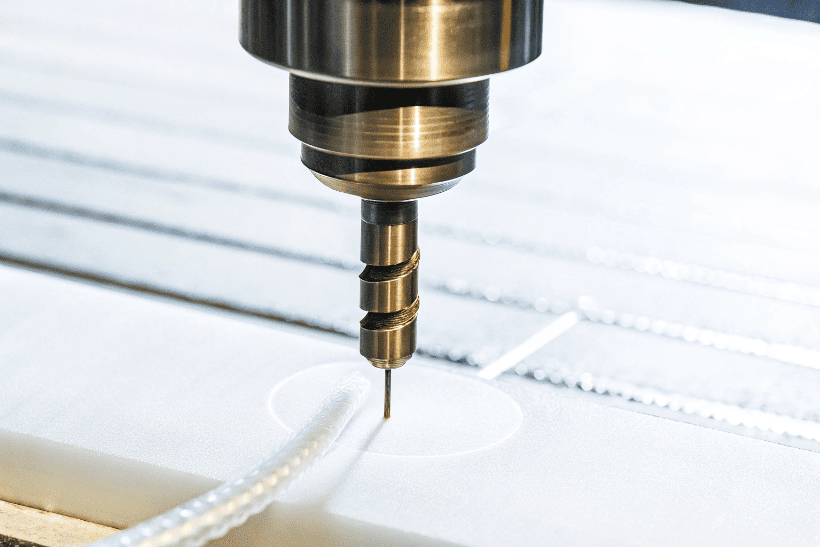

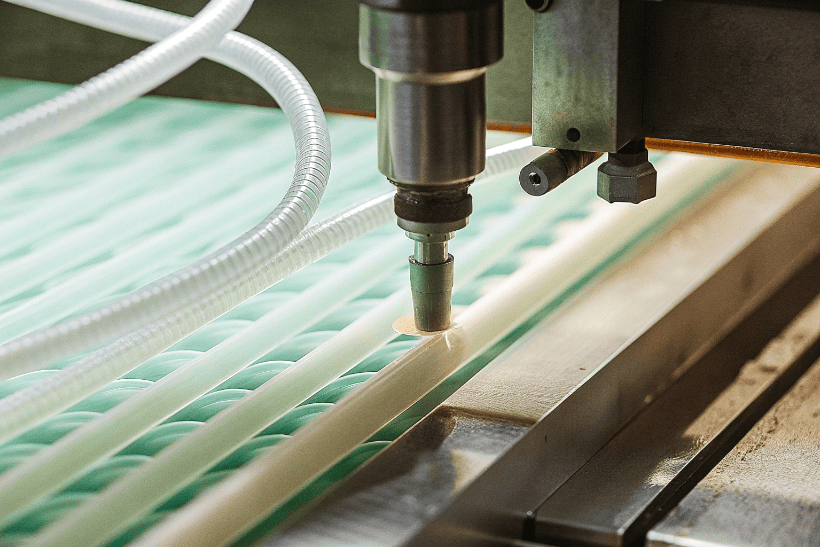

To cut medical tubing without deformation, you must use a ‘Belt-Feed’ or ‘Bush-Feed’ Cutting Machine with a thin, razor-sharp Cold Blade. Unlike roller-feed machines which crush the tube, belt systems grip the surface gently. For medical compliance, the machine must use stainless steel contact parts and oil-free mechanisms to prevent contamination.

I am Cherry from HAOXINHE. We supply computer tube cutting machine1 solutions to cleanroom factories. Let’s talk about precision.

How to Cut Medical Tubing Without Crushing It?

Standard machines use two pinch rollers.

- The Problem: To get traction, the rollers squeeze the tube. Soft silicone or PVC turns into an oval. When cut, the cross-section is not round.

- The Solution:

- Belt Feeding: Uses long upper and lower belts to spread the pressure.

- Bushing Cut: The tube passes through a steel guide (bushing) that fits it perfectly. The blade slices across the bushing face. This supports the tube so it cannot deform.

Deep Dive: Accuracy and Hygiene

1. Length Tolerance

In medical devices, 1mm error is a failure.

- Requirement: ±0.1mm tolerance.

- Tech: We use high-resolution Servo Motors for medical lines. We also use "Discharge Sensors" to confirm the piece actually fell into the bin (no static cling).

2. The "No Debris" Rule

You cannot have plastic shavings or dust inside an IV tube.

- Blade Type: We use High-Angle Razor Blades2 (similar to a scalpel). They slice cleanly rather than "chopping" or "sawing."

- No Heat: Hot cutting is banned for most medical tubes because it creates smoke residue inside the lumen (the hole). Cold cutting is mandatory.

👉 INSERT LINK: Computer Tube Cutting Machine

Industrial / Manufacturing Considerations

Stainless Steel Construction

For GMP (Good Manufacturing Practice3) compliance, your machine cannot have rusty iron parts or chipping paint.

- HAOXINHE Medical Edition: We replace the feeding tray, guides, and blade holder with 304 Stainless Steel. It is easy to sanitize with alcohol.

High Speed for Disposables

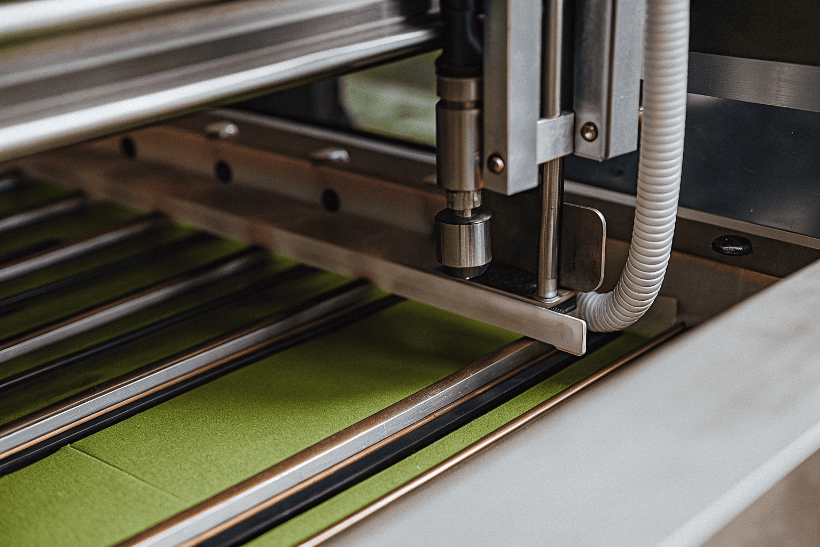

Face mask earloops and nasal cannula tubes are produced in millions.

- Throughput: Our machines can cut small diameter tubes at 140-160 pieces per minute.

- Integration: The machine can trigger a "Kick" signal to a robot arm or packing machine downstream.

How Machines Solve This Problem

We adapt our HX-Tube Series for the medical lab environment.

- Touchscreen Interface: Easy for operators wearing gloves to use.

- Batch Counting: "Cut 50, then pause for bagging." This helps operators keep count without touching the product.

- Static Control: Silicone tubes generate massive static. We install [Ionizing Bars](https://technology-ionization.simco-ion.com/products/special-application-ionizers/compact-ionizers)4 at the outlet to ensure tubes drop into the sterile bag, not on the floor.

Conclusion

To summarize, medical cutting is about "Gentle Precision." You need a machine that handles the tube like a delicate instrument, not a rope. Invest in belt-feeding and stainless steel upgrades to safeguard your compliance.

🔍 Industry Insight: What 20 Years in Medical Tubing Has Taught Us

In two decades of working with medical manufacturers, one consistent pain point stands out: “the cut ruined the tube.” It sounds simple, but in IV sets or dialysis lines, a crushed or dirty cut isn’t just cosmetic—it risks patient safety. One overlooked detail? Static electricity. It’s a silent troublemaker, causing soft silicone tubes to cling to cutters or bins, leading to missed QA counts or contamination risks. That’s why elite machines don’t just cut—they neutralize static, validate piece drop, and self-clean debris.

Another insider lesson: Medical OEMs increasingly demand post-cut traceability—meaning each tube’s length, lot code, and even blade wear data get logged. Machines with smart sensors and batch logs (like those in our HX Series) are not “nice to have” anymore—they’re contract requirements. Precision is no longer about microns; it’s about accountability.

-

Explore this link to discover advanced cutting machines that ensure precision and hygiene in medical tubing. ↩

-

Find out why High-Angle Razor Blades are essential for clean cuts in medical tubing without contamination. ↩

-

Explore the principles of GMP and their role in maintaining high standards in medical manufacturing. ↩

-

Learn how Ionizing Bars prevent static issues in medical tubing, ensuring smooth operations and quality. ↩