Universal Automatic Cutting Solution for Wires and Plastic Tubing.

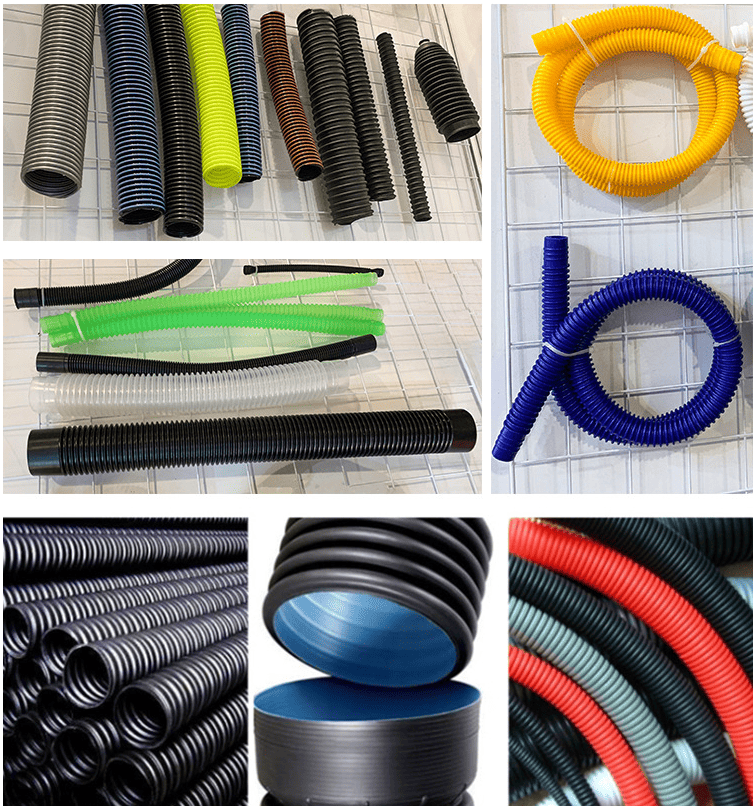

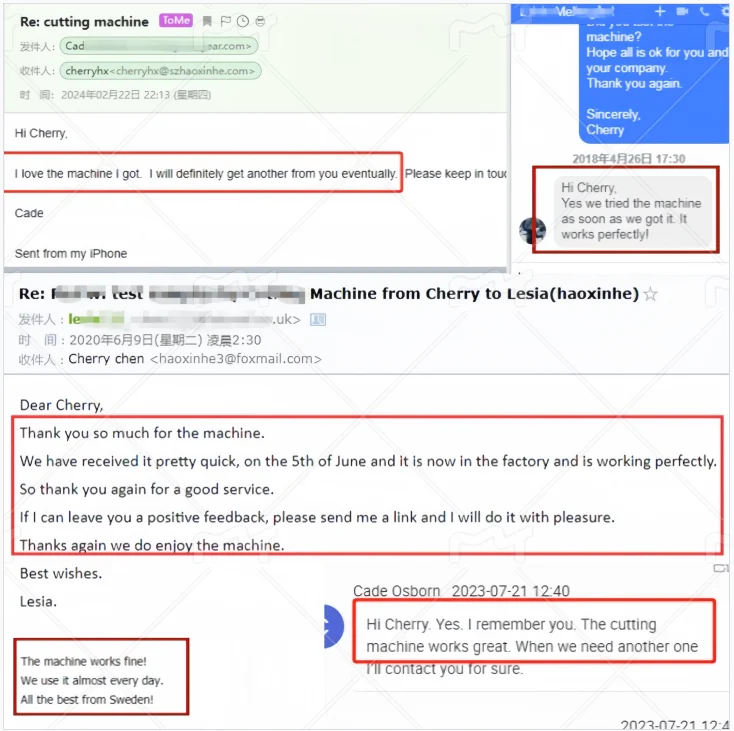

The HX-085M is a reliable micro-computer controlled cutting machine widely used in the wire harness and electronics assembly sectors. It is designed to cut materials like PVC tubes, heat shrink sleeves, fiberglass tubes, and electronic wires to precise lengths automatically.

With its user-friendly interface and robust stepper motor system, it offers a perfect balance of speed and accuracy, making it an essential tool for any production line requiring material sizing.

Key Features

- Wide Material Range: Capable of cutting both round tubes (up to Ø10-15mm) and flat strips (up to 100mm wide).

- High Accuracy: The stepper motor feeding system ensures a cutting tolerance of ±0.1mm, eliminating material waste.

- Fast Production: Operates at speeds of up to 100-120 cuts per minute, significantly outperforming manual cutting methods.

- Gentle Feeding: The pressure of the feeding rollers can be adjusted to prevent crushing soft silicone tubes or thin sleeves.

- Intelligent Control: Features automatic batch counting and auto-stop functions (when the preset batch is finished).

- Durability: Fitted with high-speed steel (HSS) blades for long-lasting sharpness on plastic and copper wire materials.

Technical Specifications

| Model | HX-085M |

|---|---|

| Max Cutting Width | 100 mm |

| Compatible Materials | PVC Tube, Heat Shrink, Wire, Fiberglass Tube, Flat Cable |

| Cutting Length | 0.1mm – 9999.9mm |

| Cutting Speed | 80 – 120 cuts/minute |

| Blade Material | High Speed Steel (HSS) |

| Voltage | AC 220V / 110V, 50/60Hz |

| Power | 350W |

Applications

Ideal for cutting materials such as:

- Insulation: Heat shrink tubing, PVC pipes, Yellow wax tubes (Fiberglass), Teflon tubes.

- Wiring: Electronic wires, flat ribbon cables, computer cables.

- Others: Nickel strips, small plastic films, rubber hoses.