Ultrasonic Cutting vs. Hot Cutting: Which Edge Seal is Better?

Are you manufacturing high-end luxury packaging, skin-contact lingerie, or medical textiles? If so, you might find that even a standard hot cut leaves an edge that is too "hard" or "scratchy" for your premium standards. This is where the debate between Ultrasonic Cutting and Hot Cutting begins.

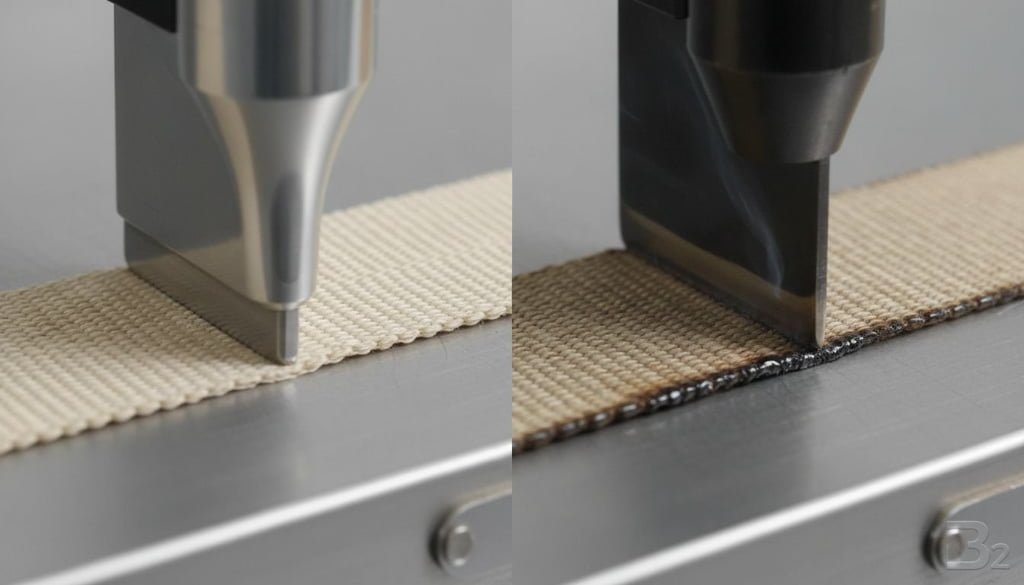

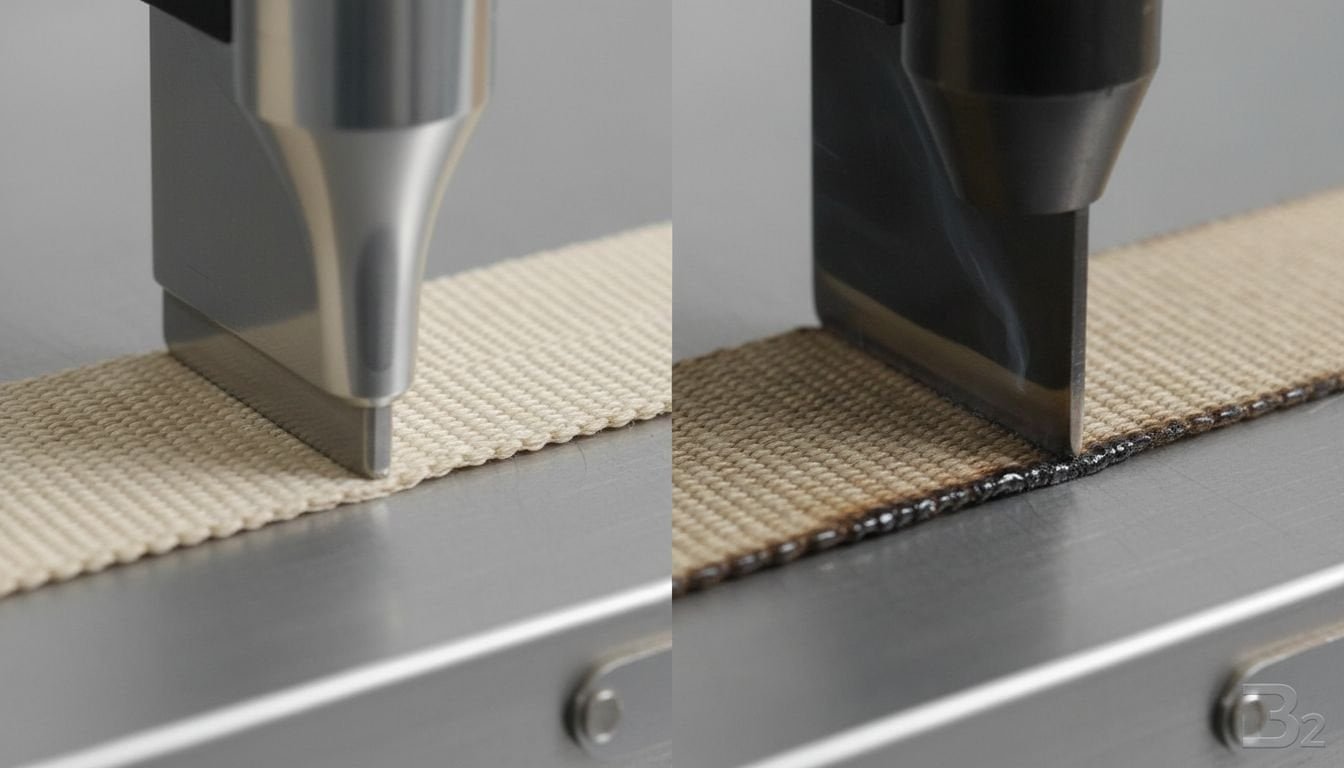

The difference between Ultrasonic Cutting and Hot Cutting is the energy source and the edge softness. Hot Cutting uses thermal heat to melt the fiber, often leaving a small, hard bead. Ultrasonic Cutting uses high-frequency vibration (20kHz+) to generate internal molecular friction, separating and sealing the fabric simultaneously. This results in a softer, flatter edge with no smoke, no discoloration, and no hard bead.

At Suzhou Haoxinhe Electrical Equipment Co., Ltd., we manufacture both types of machines. I often tell my clients: "Hot cutting is for durability; Ultrasonic is for comfort." In this guide, I will help you choose the right technology for your specific product line.

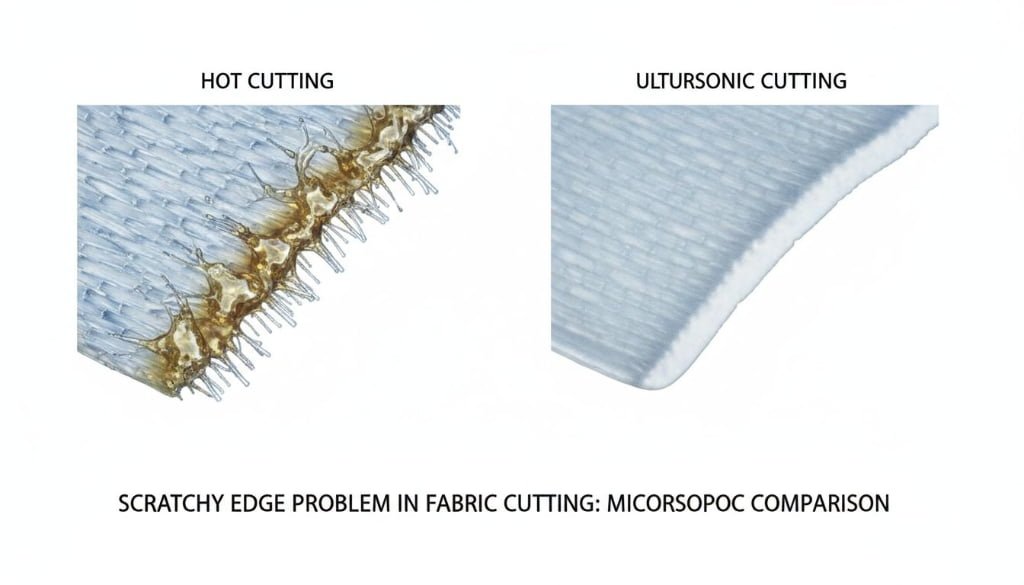

What Causes the "Scratchy Edge" Problem?

In our previous article on Hot Cutting vs Cold Cutting, we explained why heat is necessary to stop fraying on synthetics. However, heat has a side effect: the Molten Bead.

When a hot blade melts polyester or nylon, the plastic liquifies and then re-hardens. Gravity often pulls this liquid into a tiny "droplet" or ridge at the edge of the ribbon.

- For Cargo Straps: This hard edge is fine; it adds strength.

- For Bra Straps or Baby Clothes: This hard edge is a disaster. It irritates the skin and lowers the perceived value of the product.

The Physics of Ultrasonic

Ultrasonic technology does not use "heat" in the traditional sense. It uses a Sonotrode (horn) that vibrates 20,000 to 40,000 times per second. When it touches the ribbon against the anvil, this vibration excites the molecules of the plastic. The material cuts and fuses instantly from the inside out. Because there is no external heat source, the plastic doesn’t "flow" as much, resulting in an edge that is flush with the fabric surface.

Deep Dive: Comparing the Technologies

Here I will break down the operational differences. As a high-tech enterprise integrating scientific research and development, HAOXINHE has tested thousands of materials on both systems.

1. Hot Cutting (Thermal)

This is the workhorse of the industry. Our standard webbing tape cutting machine1 uses this technology.

- Mechanism: Resistance heating.

- Appearance: Can leave a slight yellow mark on white fabrics (oxidation).

- Smell: Produces smoke/fumes. Requires ventilation.

- Cost: Low maintenance, cheap blades.

- Best Application: Heavy-duty webbing, ropes, pet leashes, industrial straps.

[👉 INSERT LINK: HAOXINHE Webbing Tape Cutting Machine Series]

2. Ultrasonic Cutting (Vibrational)

This is the "Ferrari" of cutting methods. It is often found in our high-speed trademark cutting machine2 series for labels.

- Mechanism: Acoustic energy (Vibration).

- Appearance: Pristine white edges, no yellowing, soft to the touch.

- Smell: Zero smoke, zero smell. Eco-friendly.

- Cost: Higher initial investment. The generator and horn are expensive components.

- Best Application: Lingerie elastic, luxury gift ribbons, medical bandages, printed labels.

[👉 INSERT LINK: HAOXINHE Ultrasonic Label Cutting Machine]

Technical Specification Comparison

| Feature | Hot Cutting | Ultrasonic Cutting |

|---|---|---|

| Edge Feel | Hard / Beaded | Soft / Flat |

| Color Preservation | Risk of Yellowing | Perfect Color Retention |

| Smoke/Fumes | Yes (Need Ventilation) | None |

| Cutting Speed | Medium to High | Very High |

| Maintenance | Low (Change Blade) | Medium (Tuning Generator) |

| Machine Cost | $$ | $$$$ |

If you are running a computer tube cutting machine for industrial PVC tubes, hot cutting is sufficient. But if you are producing high-end satin labels for Armani or Gucci, you cannot use a hot knife. You must go Ultrasonic.

Industrial / Manufacturing Considerations

When scaling up production, you need to consider Stability and Cost of Ownership.

The Stability Challenge

Hot cutting is simple. If the blade gets dull, you sharpen it. If the heater breaks, you replace it for $20.

Ultrasonic is complex. The "Horn" (the cutting die) must be perfectly tuned to the frequency of the generator. If your operator drops the horn or tightens it incorrectly, it can crack, costing hundreds of dollars to replace.

Cherry’s Story: The Medical Client

I had a client in Germany manufacturing straps for medical face masks. They started with our standard hot and cold cutting machine. The problem was that the mask straps were irritating the users’ ears after 8 hours of wear. The "hard bead" from the hot cut was the culprit.

We upgraded them to a customized HAOXINHE Ultrasonic Cutting line.

- Result: The edge became velvety soft.

- Benefit: Customer complaints dropped to zero.

- Bonus: Because ultrasonic seals without smoke, their cleanroom classification3 was easier to maintain.

Versatility in Shapes

Ultrasonic is not just for straight cuts. Our different shapes cutting machine4 uses ultrasonic dies to punch out flowers, circles, or stars from ribbon without any fraying. This is impossible with a standard hot blade unless you use a laser (which burns the edges brown).

[👉 INSERT LINK: Different Shapes Cutting Machine]

How Machines Solve This Problem

At HAOXINHE, we don’t force you into one technology. We offer both.

For general industrial use, our HX-980 Automatic Hot Cutter is the bestseller. It’s robust and reliable.

However, for clients demanding the "Soft Edge," we offer the HX-2000 Ultrasonic Series5.

Hybrid Solutions

We even have machines that combine technologies. For example, a rotary bevel cutting machine6 that uses heat to slice through thick safety belts at an angle, while a secondary station punches holes. Or a wire cutting and stripping machine that handles the electrical components of your product assembly.

Key features of our Ultrasonic line:

- Auto-Frequency Tracking: The generator automatically adjusts to the horn’s condition, preventing overload.

- Titanium Horns: We use high-grade titanium alloy for durability, unlike cheap aluminum horns that wear out in a week.

- Cooling Systems: Integrated air cooling to keep the transducer stable during 24/7 operation.

Conclusion

To summarize, the choice depends on your customer’s skin. Does the product touch the skin? If yes, choose Ultrasonic for a soft seal. Is it for heavy-duty load bearing? Choose Hot Cutting for a strong, fused seal.

Cherry’s Insights for Google Snippet

Ultrasonic Cutting is superior to Hot Cutting for applications requiring a soft, non-irritating edge, such as clothing labels, underwear, and medical textiles. While Hot Cutting is cheaper and effective for heavy webbing, it leaves a hard, beaded edge that can scratch the skin. Ultrasonic technology uses high-frequency vibration to seal the fabric without heat or smoke, preserving the material’s original color and softness. For premium textile manufacturing, HAOXINHE recommends upgrading to ultrasonic solutions.

-

Find out how webbing tape cutting machines operate and their applications in various industries. ↩

-

Explore the capabilities of high-speed cutting machines for efficient label production. ↩

-

Understand the benefits of Ultrasonic Cutting in maintaining cleanroom standards. ↩

-

Discover the versatility of machines that can cut various shapes without fraying. ↩

-

Learn about the advanced features of the HX-2000 Ultrasonic Series for premium cutting. ↩

-

Explore the functionality and applications of rotary bevel cutting machines in manufacturing. ↩

[…] but fear the "yellow edge" of lasers, we recommend Ultrasonic Cutting (as discussed in Day 2). It is the true premium […]

we also have it, we can share with you video