What are the best devices to cut ribbon with?

Ribbon cutting looks simple, but once production volume increases, problems appear fast: uneven lengths, frayed edges, slow output, and rising labor costs. Manual tools create rework and waste. The right cutting device brings consistency, speed, and predictable quality to your ribbon production.

The best devices to cut ribbon are those that deliver repeatable length control, clean edges, and stable performance—ranging from heated ribbon cutters and electric cutters to fully automated ribbon cutting machines, selected based on ribbon material and production volume.

In this article, I will share practical, production-tested options for cutting ribbon and explain how each device solves specific manufacturing problems compared with manual cutting.

What can I use to cut ribbon?

Ribbon materials vary widely—satin, polyester, nylon, grosgrain, woven ribbon, decorative ribbon, and even coated or adhesive-backed types. Using the wrong cutting method leads to fraying, melted edges, length deviation, or low efficiency.

You can use manual tools for low volume, but for stable and scalable production, electric ribbon cutters, hot cutting machines, and automated ribbon cutting systems are the most reliable solutions.

To choose correctly, the key question is not “Can it cut?” but “Can it cut consistently, fast, and without waste?” Below, I break down the main options using a clear problem-vs-solution approach.

Why do manual ribbon cutting tools fail in production?

Manual tools such as scissors, rotary craft cutters, or knives are commonly used at the beginning. They seem cheap and flexible, but problems appear quickly once output increases.

Problem:

Manual cutting depends entirely on the operator. Length control relies on visual judgment. Cutting force changes with fatigue. Edges fray easily, especially on synthetic ribbons.

Solution:

Production-grade ribbon cutting devices remove human variability and apply controlled force, speed, and positioning every cycle.

| Item | Manual Cutting | Machine Cutting |

|---|---|---|

| Length accuracy | ±3–5 mm | ±0.5–1 mm |

| Edge quality | Fraying common | Clean or sealed |

| Speed | 10–20 pcs/min | 80–120 pcs/min |

| Labor cost | High | Low |

| Repeatability | Unstable | Consistent |

From an engineering perspective, manual cutting has no closed-loop control. Machines introduce mechanical guides, feeding rollers, and controlled blades that stabilize output.

Heated ribbon cutters: when edge sealing matters?

Synthetic ribbons such as polyester or nylon tend to fray after cutting. This is a common complaint from packaging and decorative ribbon producers.

Problem:

Cold cutting leaves open fibers. Additional sealing or rework is required.

Solution:

Heated ribbon cutters use a hot blade to cut and seal the edge in one step.

A heated cutter melts the ribbon edge slightly, preventing fiber separation. This is especially effective for satin ribbon, decorative ribbon, and label ribbon.

| Feature | Manual Scissors | Heated Cutter |

|---|---|---|

| Fraying | Severe | None |

| Extra process | Required | Not needed |

| Operator skill | High | Low |

| Edge consistency | Unstable | Stable |

From my experience, many customers start with scissors and then add a separate sealing process. Once they switch to a hot cutting machine, the entire step is eliminated, saving time and reducing defect rates.

Electric ribbon cutting machines: balancing speed and control?

When production volume increases to hundreds or thousands of pieces per day, handheld tools become a bottleneck.

Problem:

Manual measurement and cutting cannot keep up with order volume. Length inconsistency causes downstream packaging issues.

Solution:

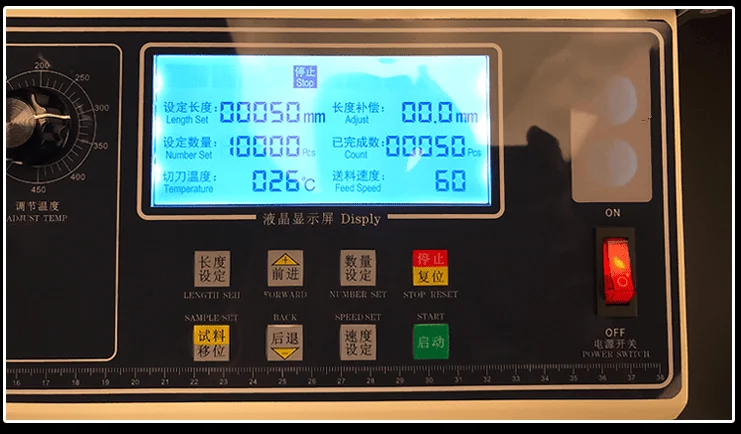

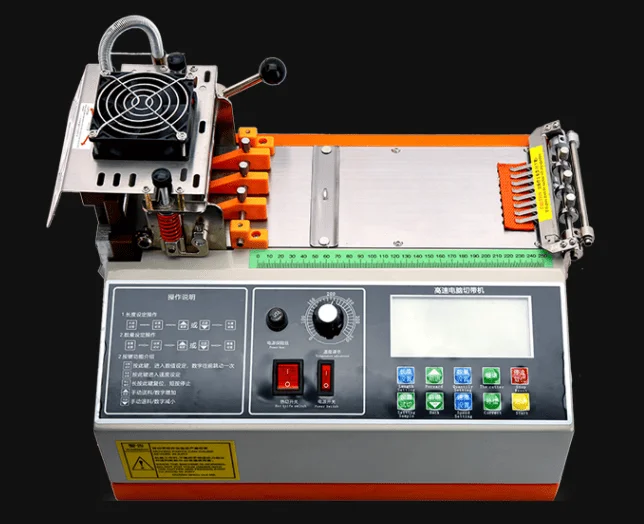

Electric ribbon cutting machines combine motor-driven feeding with controlled blade movement.

These machines allow the operator to set cutting length digitally. Ribbon is fed automatically, measured precisely, and cut at high speed.

Typical technical benefits include:

- Length tolerance within ±0.5–1 mm

- Cutting speed up to 100–120 pcs/min (based on 50 mm length)

- Stable feeding for soft or slippery ribbons

| Aspect | Manual Cutting | Electric Cutter |

|---|---|---|

| Speed | Slow | High |

| Length setting | Visual | Digital |

| Scrap rate | High | Low |

| Operator fatigue | High | Minimal |

In real production environments, this directly translates to better delivery reliability and predictable output planning.

Automated ribbon cutting systems: when scale demands precision?

For factories producing ribbon continuously or integrating cutting into a production line, standalone machines are still not enough.

Problem:

Manual loading and unloading limits throughput. Inconsistent feeding causes jams or miscuts.

Solution:

Fully automated ribbon cutting systems integrate feeding, measuring, cutting, and optional stacking.

These systems are designed for industrial-scale production. Once parameters are set, the machine runs continuously with minimal intervention.

Key technical advantages:

- Servo-controlled feeding for stable tension

- Programmable length and quantity

- Consistent burr-free or sealed cuts

- Easy integration with packaging or labeling lines

| Metric | Semi-Automatic | Fully Automated |

|---|---|---|

| Daily output | Medium | High |

| Operator involvement | Required | Minimal |

| Length deviation | Low | Very low |

| ROI at scale | Moderate | High |

I have worked with customers who cut thousands of ribbon pieces per shift. After automation, labor was reduced by more than 50%, and material waste dropped significantly due to stable feeding control.

How do you choose the right ribbon cutting device?

The correct choice depends on three technical factors:

-

Ribbon material

- Synthetic ribbon → hot cutting recommended

- Natural fiber ribbon → cold cutting preferred

-

Production volume

- Low volume → electric cutter

- Medium volume → automatic cutter

- High volume → fully automated system

-

Quality requirement

- Decorative or branded ribbon → sealed, clean edges

- Industrial ribbon → length accuracy and speed

From an engineering perspective, investing in the right machine early avoids repeated upgrades and process redesign later.

Conclusion

The best devices to cut ribbon depend on material, volume, and quality targets. Heated cutters solve fraying, electric cutters improve speed and consistency, and automated systems deliver stable, scalable production with predictable ROI.

Call to Action (CTA)

If you are struggling with ribbon cutting efficiency or edge quality, send us your ribbon material samples for a free test cut or contact our engineering team for a custom cutting solution.

📩 Email: sales@yourcompany.com

I am Cherry from Cutopix (HAOXINHE). With over 12 years of experience in automated cutting equipment, I am ready to help you optimize your ribbon cutting process with the right machine—not guesswork.

[…] looking for equipment, you might wonder what are the best devices to cut ribbon with. Here is a direct breakdown of manual tools versus […]

It is ok, we can share with you video of cutting machine.Whatsapp: +8613270987536