What Can I Use to Cut Ribbon?

Are you struggling with frayed edges, uneven lengths, and slow production rates when cutting ribbons with basic tools like scissors or manual cutters? Using the wrong equipment for industrial ribbon cutting leads to high material waste, inconsistent product quality, and frustrating labor bottlenecks.

To cut ribbon effectively in a manufacturing setting, especially synthetic types like satin, nylon, or polyester, you must use thermal cutting tools rather than cold mechanical blades. Options range from handheld hot knives for low-volume crafting to fully automated hot knife cutting machines that cut and seal the edges simultaneously with high precision and speed for mass production.

In this article, I will break down the different tools available for cutting ribbon from an industrial perspective, explaining why standard methods fail and how automated thermal technology provides the professional, durable finish required for mass production.

Why standard scissors fail to cut ribbon cleanly?

Do your cut ribbons immediately start unraveling into loose threads after using standard scissors or guillotine cutters? This mechanical failure destroys product quality and forces expensive rework.

Standard scissors use a "cold cut" method that mechanically severs the woven synthetic fibers without applying heat. Without thermal energy to fuse these synthetic fibers together at the cut point, the tension in the weave is released, causing the individual threads to unravel and fray immediately upon cutting.

Moving from Manual Tools to Automated Solutions

In my 12 years of experience at HAOXINHE, I have seen countless production managers try to scale up operations using manual tools, only to face severe quality control issues. They often ask me, "What can I use to cut ribbon faster without sacrificing the edge?" The answer depends entirely on your production volume and material specifications.

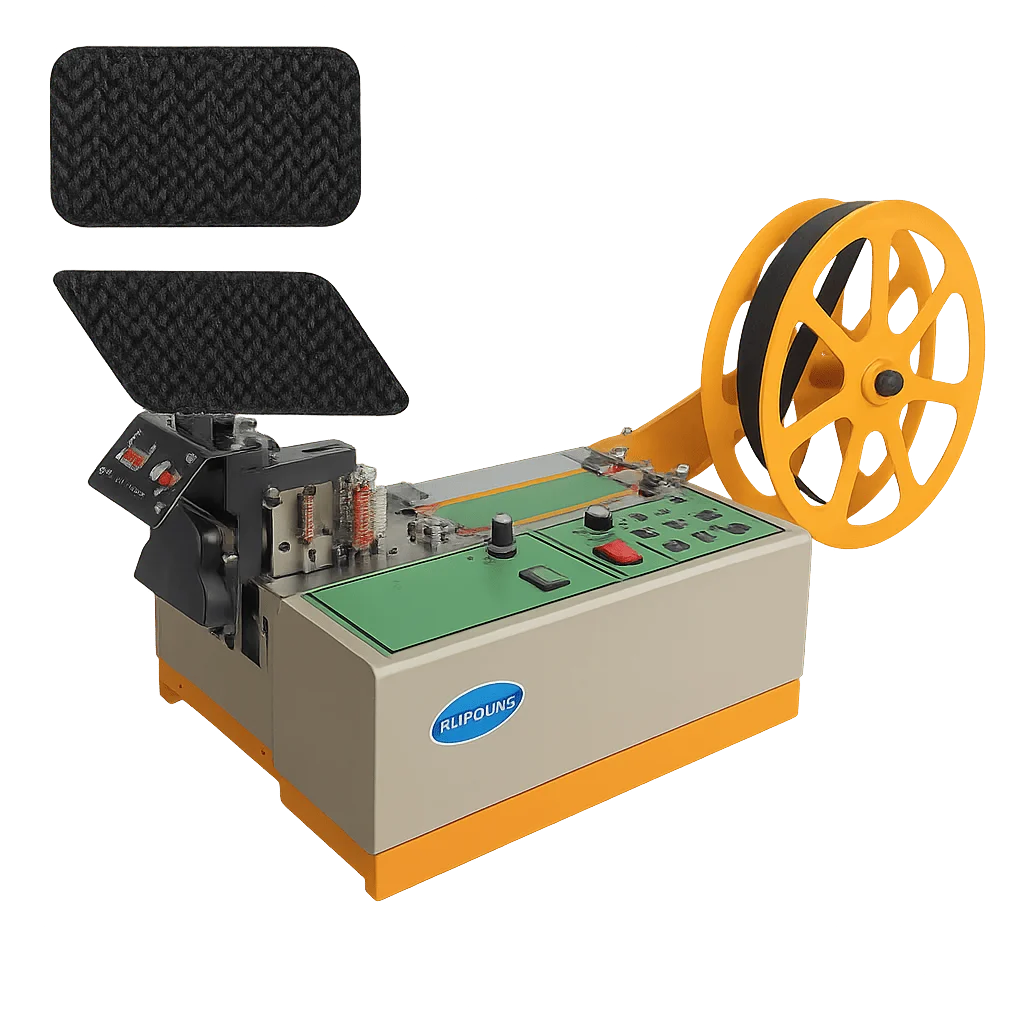

When dealing with synthetic materials like satin ribbon, grosgrain, or heavy-duty webbing, you must move beyond "cold cutting." You need a solution that cuts and seals simultaneously. We can categorize ribbon cutting tools into three main industrial tiers. While a handheld hot knife solves the basic fraying issue by melting synthetic fibers, it introduces significant human error—inconsistent operator speed leads to burnt, hard edges or incomplete seals.

For industrial applications where tolerance and consistency are paramount, automation is not just a luxury; it’s a necessity. An automated machine removes the operator variable, ensuring the dwell time of the blade and the cutting temperature are identical for every single piece, whether you are cutting 100 pieces or 10,000.

Below is a comparison of the common tools used in the industry and why upgrading to automation is often the necessary step for growing manufacturers.

| Tool Category | Cutting Method | Edge Quality Result | Production Throughput | Ideal Use Case |

|---|---|---|---|---|

| Standard Scissors / Guillotine | Cold Mechanical Crush | Frayed, loose threads. Requires post-processing (gluing/singeing). | Very Slow, labor-intensive. | Prototyping or natural fibers (cotton) that don’t melt. |

| Handheld Hot Knife | Manual Thermal Cut | Sealed but Inconsistent. Risk of burns or hard, scratchy edges due to human error. | Slow to Medium. Relies on operator skill. | Low volume production, custom shapes, or on-site repairs. |

| Automated Ribbon Cutter (Cutopix) | Automated Thermal Cut & Seal | Perfectly Sealed, uniform, soft edges. High length precision (±0.1mm). | Very High. Continuous automatic feeding and cutting. | High-volume manufacturing, strict quality control requirements. |

As the table illustrates, while you can use scissors or handheld tools, they are bottlenecks for serious manufacturing. If your goal is efficiency and consistent quality without the headache of fraying, an automated hot knife system is the required tool.

Conclusion

To summarize, to achieve professional, non-fraying results when cutting synthetic ribbon, you must abandon cold cutting tools like scissors. Transitioning to thermal cutting solutions is essential, and for high-volume manufacturing, adopting automated machines is the only way to ensure consistent quality, precise tolerances, and efficient production speed.

Call to Action (CTA)

Are you unsure if an automated hot knife is right for your specific ribbon material or production volume? Don’t guess based on generic advice. Send your actual material samples to HAOXINHE today for a free test cut. Our engineering team will process your material on our machines and provide a detailed report and video of the results so you can see the edge quality firsthand. Contact us directly via our website or email to arrange your test.

Hi, this is a comment.

To get started with moderating, editing, and deleting comments, please visit the Comments screen in the dashboard.

Commenter avatars come from Gravatar.