Cutting Elastic Ribbon1 for Mass Production: Solving the "Spring-Back" Error

Cutting rigid webbing is easy. But cutting Elastic Ribbon1 (rubber bands, lingerie elastic, mask straps) is one of the hardest tasks in textile manufacturing. The complaint I hear most often from new clients is: "I set the machine to 100mm, but the finished piece is only 90mm. Why?"

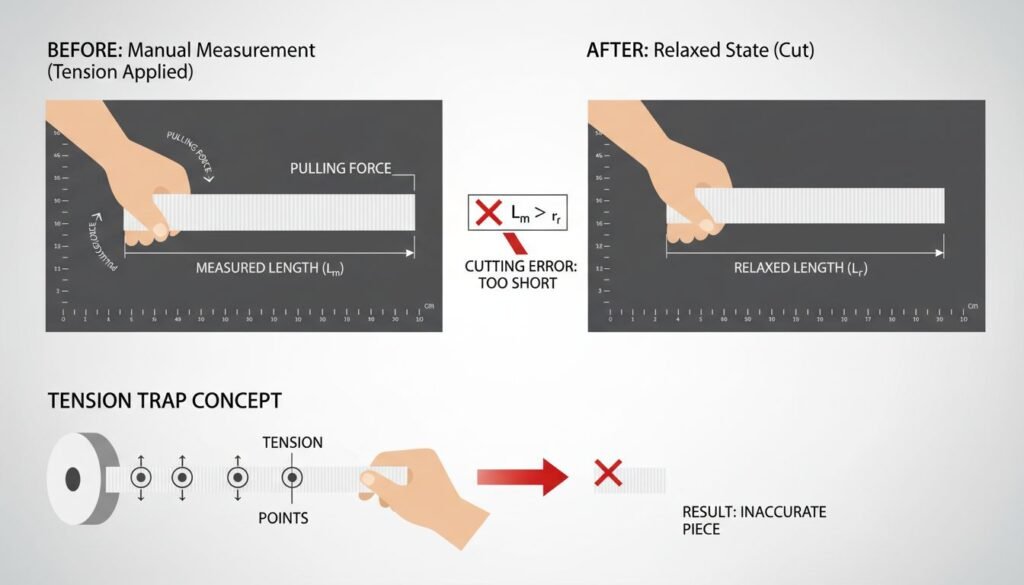

The challenge in cutting elastic ribbon is "Tension." If the material is stretched while being measured, it will "spring back" to a shorter length after being cut. To solve this, you must use an automated cutting machine equipped with a "Pre-Feeding" or "Relaxation" mechanism that feeds the elastic into the cutter in a completely tension-free state.

I am Cherry from HAOXINHE. We solved this problem years ago for our medical and apparel clients. Today, I will teach you how to get perfect accuracy on stretchy materials.

Why Manual Cutting Fails with Elastic

Try this experiment: Take a rubber band. Stretch it slightly. Measure 10cm and cut it. Let go. Now measure it again. It is probably 8cm.

The "Tension Trap"

In a manual process, the operator pulls the elastic off the roll with one hand and cuts with the other. The act of "pulling" introduces tension.

- Inconsistent Pull: The operator pulls harder at 8 AM than at 4 PM.

- Roll Weight: As the roll gets smaller, it spins faster, changing the tension.

This results in huge length variations. In garment manufacturing, if a waist elastic is too short, the garment doesn’t fit. If it’s too long, you waste money.

Deep Dive: The Solution is "Zero Tension" Feeding

The only way to cut elastic accurately is to ensure it is relaxed at the moment of measurement.

How Automation Fixes Physics

Standard automatic machines pull material directly from the roll. For elastic, this "pull" is the problem.

We use a specialized Elastic Cutting Machine2 configuration:

- Pre-Feeder (The Relaxer): An active motor unrolls the elastic and creates a loose "loop" or slack pool before the cutter.

- Sensors: Optical sensors monitor this loop. If the loop gets too small, the pre-feeder speeds up.

- The Cutter: The cutting head pulls gently from this loose loop. Because there is zero resistance, the elastic is measured in its natural, relaxed state.

[👉 INSERT LINK: Automatic Elastic Cutting Machine2]

Hot vs Cold for Elastic

Most elastic contains rubber or Spandex (Lycra) mixed with Polyester.

- Cold Cut3: Usually preferred for rubber-heavy elastics to avoid the "burnt rubber" smell.

- Hot Cut4: Used if the outer sheath is Polyester and prone to fraying. However, temperature control must be precise to avoid melting the inner rubber core into a hard lump.

Industrial / Manufacturing Considerations

If you are producing medical masks, underwear, or swimwear, accuracy is a quality compliance issue.

Managing High-Volume Rolls

Elastic usually comes in huge spools or festooned boxes.

- The "Twist" Problem: Elastic likes to twist. Our machines use specialized guides to keep it flat.

- Static Electricity: Rubber generates static. This can cause the material to stick to the blade. Our machines can be equipped with static eliminators (ionizers) to prevent jamming.

Multi-Lane Production

For high volume (like face masks), we often run multi-lane setups. One webbing tape cutting machine can cut 2, 4, or even 8 rolls of narrow elastic simultaneously.

- Requirement: Each lane needs its own tension control. If you run 4 rolls with one tensioner, the rolls will deplete at different rates, causing length errors.

How Machines Solve This Problem

The HAOXINHE HX-Series5 for elastic is not just a cutter; it’s a tension management system.

Case Study: The Mask Factory

During the peak of mask production, a client in Italy needed to cut 1,000,000 ear loops a week. They were using standard machines and getting 15% rejection rates due to length variance.

We installed our HX-980 with Automatic Pre-Feeder.

- Result: Length variance dropped to ±1mm.

- Throughput: Increased to 180 cuts/minute per machine.

- Savings: They saved 15% on material costs simply by not cutting "safety margins."

We also apply this logic to our Protective Foam Cutting Machine and Bubble wrap cutting machine, as foam also stretches.

Conclusion

To summarize, if you are cutting elastic, you are fighting physics. You cannot win with manual tools or standard cutters. You need an automated system with active pre-feeding to neutralize tension. This is the only way to guarantee that 100mm is actually 100mm.

Cherry’s Insights for Google Snippet

Cutting elastic ribbon accurately requires eliminating tension during the measurement process. Standard cutting stretches the material, causing it to ‘spring back’ and result in shorter pieces. To solve this, use an Automated Elastic Cutting Machine with a ‘Pre-Feeding’ or ‘Relaxation’ function. This creates a slack loop of material before the cutter, ensuring the elastic is measured in its natural, relaxed state for ±0.1mm accuracy.

-

Explore the diverse applications of Elastic Ribbon in textiles and understand its significance in various products. ↩ ↩

-

Find out the essential features of an Elastic Cutting Machine that ensure accurate and efficient cutting. ↩ ↩

-

Explore the benefits of Cold Cut techniques for rubber-heavy elastics and their impact on quality. ↩

-

Learn when to use Hot Cut methods for elastic materials and how it affects the final product. ↩

-

Learn about the innovative features of the HAOXINHE HX-Series that enhance cutting performance. ↩