Hot Cutting vs Cold Cutting for Ribbon: Which Is Better for Industrial Use?

Choosing the right ribbon cutting method is critical in industrial and manufacturing environments. The cutting process not only affects edge quality, but also production speed, material waste, and overall cost.

In this article, we compare hot cutting and cold cutting for ribbon in real manufacturing scenarios, helping you decide which method works best for your materials and production needs.

What Is Hot Cutting for Ribbon?

Hot cutting uses a heated blade to cut ribbon while sealing the edge at the same time. The heat melts synthetic fibers, preventing them from unraveling after cutting.

How Hot Cutting Works

- A blade is heated to a controlled temperature

- Ribbon is fed into the cutting area

- The cut edge is sealed instantly by heat

Materials Suitable for Hot Cutting

Hot cutting is ideal for ribbons made of synthetic fibers, including:

- Polyester ribbon

- Nylon webbing

- Elastic tapes

- Woven synthetic straps

These materials respond well to heat and form clean, sealed edges.

What Is Cold Cutting for Ribbon?

Cold cutting relies on a sharp mechanical blade without applying heat. The ribbon is sliced cleanly using pressure alone.

How Cold Cutting Works

- A sharp blade cuts through the ribbon

- No heat is involved in the process

- Edge quality depends on blade sharpness and material type

Materials Suitable for Cold Cutting

Cold cutting works best for:

- Cotton ribbon

- Natural fiber tapes

- PVC tubes or flat materials

- Heat-sensitive ribbons

Because no heat is applied, cold cutting avoids thermal damage to delicate materials.

Hot Cutting vs Cold Cutting: Key Differences

| Feature | Hot Cutting | Cold Cutting |

|---|---|---|

| Edge sealing | Yes | No |

| Fraying prevention | Excellent | Depends on material |

| Heat damage risk | Low (controlled) | None |

| Best materials | Synthetic fibers | Natural or heat-sensitive fibers |

| Production speed | High | High |

| Maintenance needs | Temperature control | Blade sharpness |

Both methods can be effective, but the choice depends heavily on ribbon material and production requirements.

Which Cutting Method Is Better for Industrial Ribbon Cutting?

There is no single best method for all situations. Manufacturers should consider:

- Ribbon material type

- Required edge quality

- Daily cutting volume

- Production consistency needs

For synthetic ribbons that must remain sealed and clean after cutting, hot cutting is usually the preferred solution. For natural fibers or materials that cannot tolerate heat, cold cutting provides reliable results.

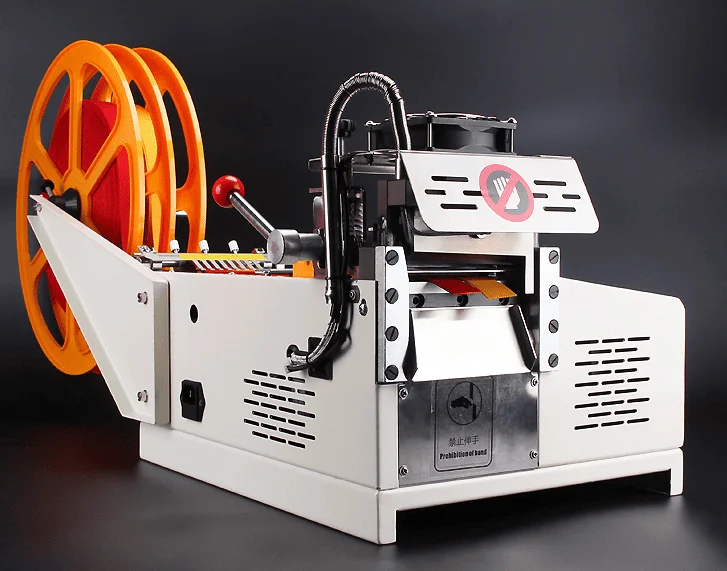

How Ribbon Cutting Machines Improve Consistency

In industrial settings, manual cutting methods often lead to inconsistent lengths and uneven edges. Automated ribbon cutting machines solve these problems by:

- Maintaining consistent cutting speed

- Controlling blade temperature or pressure

- Reducing human error

- Increasing overall production efficiency

Manufacturers often choose different machines depending on whether hot cutting or cold cutting is required.

→ https://cutopix.com/product/hx-95m-hot-cold-ribbon-label-plastic-cutting-machine/

→ https://cutopix.com/product/hx-chs02-velcro-round-shape-cutting-machine/

Final Recommendation

If your production involves synthetic ribbons and requires sealed edges, hot cutting is generally the better option. For natural fibers or heat-sensitive materials, cold cutting remains the most practical and reliable method.

Understanding the difference between hot cutting and cold cutting helps manufacturers improve quality, reduce waste, and choose the right ribbon cutting solution for long-term production success.