Multi-Shape Cutting vs. Straight Cutting: Beyond the Square Edge

In the world of industrial textiles, a straight cut is "functional," but a shaped cut is "professional." Whether it’s the rounded corner of a Velcro strap or the chevron (V-shape) end of a luxury satin ribbon, shapes add value.

The difference between Straight Cutting and Multi-Shape Cutting is tooling. Straight cutting uses a simple linear blade (guillotine). Multi-Shape Cutting uses specialized dies (molds) or ultrasonic punches to create geometries like circles, bullets, and arrowheads. While straight cutting is faster and cheaper, shape cutting eliminates secondary manual trimming.

I am Cherry from HAOXINHE. I often see factories paying workers to sit with scissors and round off the corners of thousands of straps. This is a waste of money. Let me show you how automation handles geometry.

Why You Need Shapes (The "Bullet Nose")

The most common shape request we get is the "Bullet Nose" (Rounded tip) for Velcro or webbing.

- Safety: Sharp 90-degree corners on stiff webbing can scratch the skin (e.g., on a medical wrist brace).

- Aesthetics: A V-shape cut on a satin ribbon prevents the corners from curling and looks premium.

- Function: A pointed end threads into buckles faster (as discussed in our Bevel Cutting guide.

Straight cutters physically cannot do this. You need a different machine class.

Deep Dive: Technology Options for Shapes

1. Laser Cutting1 (The Old Way)

As we discussed in Day 4, lasers can cut any shape.

- Pros: Infinite shapes without changing molds.

- Cons: Slow, yellow edges, expensive.

2. Automatic Punching/Die Cutting2 (The HAOXINHE Way)

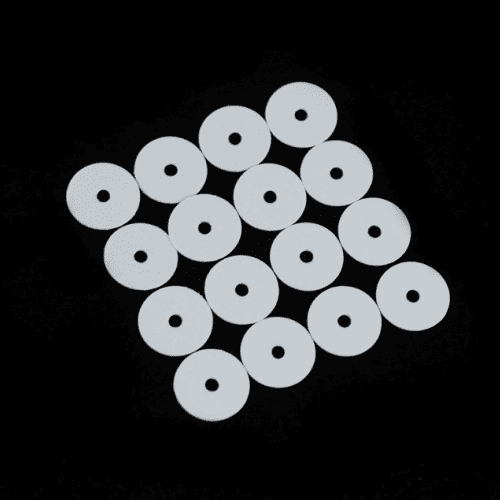

This machine acts like a cookie cutter. We install a steel mold in the shape you want (Circle, V, Round).

- Action: The webbing feeds to length -> The machine stops -> A hydraulic or pneumatic ram punches the shape -> The webbing advances.

- Heat Sealing3: The mold itself is heated! It cuts and seals the curve instantly.

- Hole Punching: We can add a hole punch in the middle of the strap in the same cycle.

👉 INSERT LINK: Automatic Punching and Cutting Machine

Comparison Table

| Feature | Straight Cutter | Shape/Punching Cutter |

|---|---|---|

| Edge Geometry | Linear (90° or 45°) | Any (Round, V, Hole) |

| Tooling | Standard Blade | Custom Mold Required |

| Changeover | Instant | 10-15 Minutes (Swap Mold) |

| Speed | 100-120 cuts/min | 60-90 cuts/min |

| Cost | $ | $$ |

Industrial / Manufacturing Considerations

Upgrading to shape cutting requires a mindset shift.

The "Mold" Strategy

With a straight cutter, you are flexible. With a Shape cutter, you are committed.

If you order a "25mm Round" mold, you can only cut 25mm webbing. If you get a 30mm order, you need a new mold.

- Our Solution: HAOXINHE designs "Quick Change" mold sets. We also offer different shapes cutting machine models that use a rotating turret or multi-die setup for factories with diverse products.

Waste Management4

Straight cutting has zero waste (Blade width is negligible).

Shape cutting creates "slugs" or "chips" (the material removed to make the curve).

- Impact: You lose about 5-10mm of webbing per cut. On a 10,000 piece run, this adds up to 50-100 meters of waste. You must account for this in your costing.

How Machines Solve This Problem

Our HX-Punch Series integrates three steps into one:

- Feed: Precise length measurement.

- Hole Punch: Punching a 5mm hole for a grommet.

- Shape Cut: Cutting the "Bullet Nose" end.

This replaces three workers: the Cutter, the Hole Puncher, and the Corner Trimmer.

We even apply this logic to Protective Foam Cutting Machine5 applications where foam pads need specific contours for packaging.

Conclusion

To summarize, Straight Cutting is for volume; Shape Cutting is for value. If your product touches the skin or needs to look premium, investing in an Automatic Punching/Shape Cutting Machine is the only way to scale without an army of manual trimmers.

Cherry’s Insights for Google Snippet

For ribbons and webbing requiring rounded corners, V-shapes, or holes, a standard straight cutter is insufficient. Manufacturers should use an Automatic Punching/Die Cutting Machine equipped with heated molds. These machines ‘punch’ the specific shape and seal the edge in one action, eliminating the need for slow, manual corner trimming or expensive laser cutting. While tooling (molds) is required for each width, the labor savings on secondary operations are massive.

-

Understand the advantages and limitations of Laser Cutting for various textile shapes. ↩

-

Find out how Automatic Punching/Die Cutting improves efficiency and reduces labor costs. ↩

-

Learn about Heat Sealing technology and its role in enhancing product durability. ↩

-

Explore effective waste management strategies to minimize costs in textile manufacturing. ↩

-

Learn about the applications of Protective Foam Cutting Machines in various industries. ↩