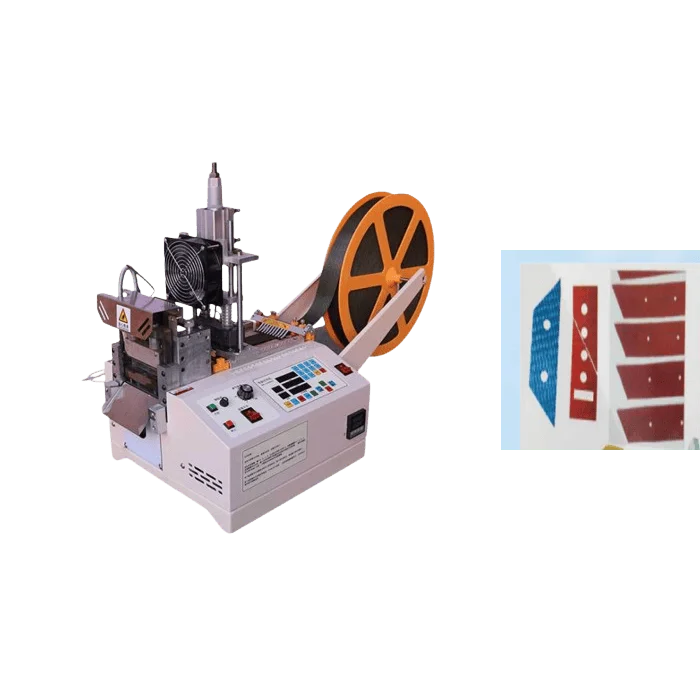

Professional Solution for Manufacturing Velcro Cable Ties and Cord Organizers.

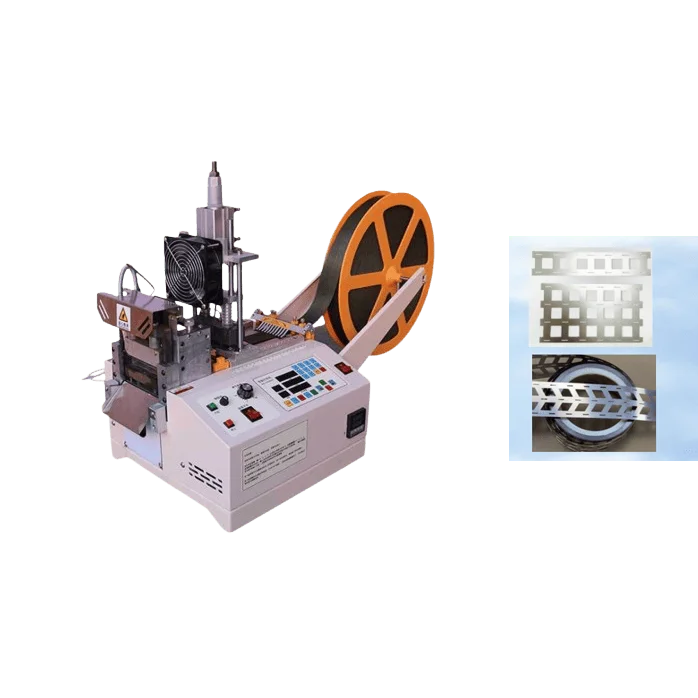

This machine is specifically designed to produce “Cat Eye” style cable ties (also known as T-type or P-type straps) from back-to-back Velcro rolls. It performs punching, shaping, and cutting in a single automatic process.

It punches the “eye” (slot) in the head of the strap and shapes the tail (round or chamfered), creating a finished, reusable cable tie ready for packaging. It is the ideal equipment for manufacturers of cable management accessories.

Key Features

- All-in-One Processing: Automatically punches the internal slot (“Cat Eye”) and cuts the outer shape simultaneously.

- Precise Positioning: Uses high-sensitivity sensors to ensure the hole is perfectly centered on every strap.

- Waste Removal System: Automatically discharges the punched waste material (the small piece from the hole) to keep the operation clean.

- High Efficiency: Capable of producing large volumes of cable ties with consistent quality, replacing slow manual die presses.

- Adjustable Settings: Cut length and quantity can be easily set via the digital control panel.

Technical Specifications

| Model |

HX-200DK-A1(Customizable) |

|---|---|

| Compatible Material | Back-to-Back Velcro (Double-sided Hook & Loop) |

| Max Material Width | 10 – 50 mm (Standard for cable ties) |

| Punching Shape | Cat Eye, Square Hole, Round Hole (Depends on Mold) |

| Cutting Speed | 60 – 100 pieces/minute |

| Cutting Length | Adjustable (e.g., 150mm, 200mm, 300mm) |

| Voltage | AC 220V / 110V, 50/60Hz |

| Air Pressure Needed | Yes (for waste removal) |

Applications

Mainly used for producing reusable cable ties for:

- Data Center Cable Management: Organizing Ethernet and server cables.

- Home & Office: Computer wire organizers, charger cord straps.

- Audio/Video: Managing microphone and speaker cables.