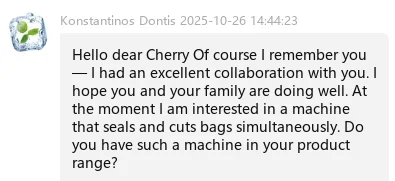

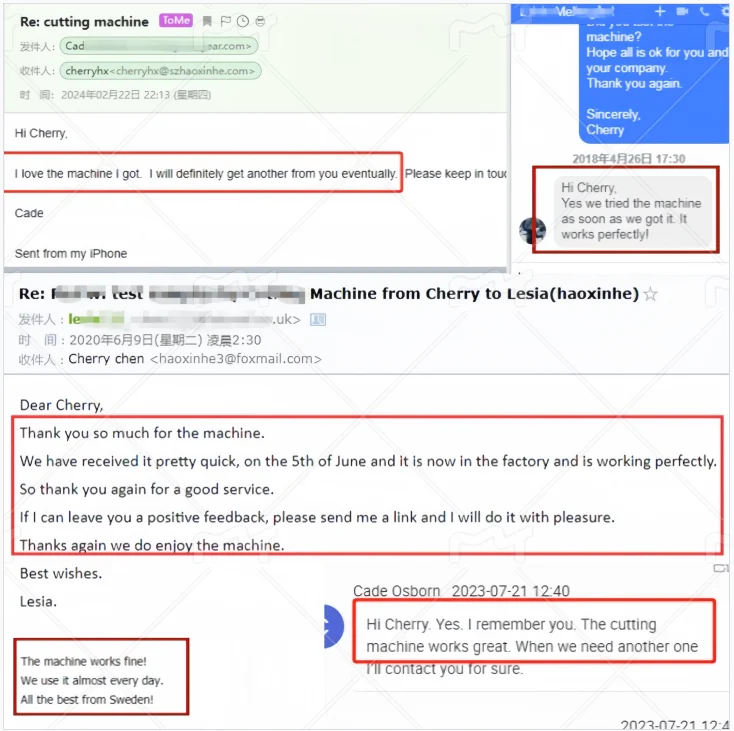

Automatic Die Punching & Cutting Solution for EVA Foam and Rubber Gaskets.

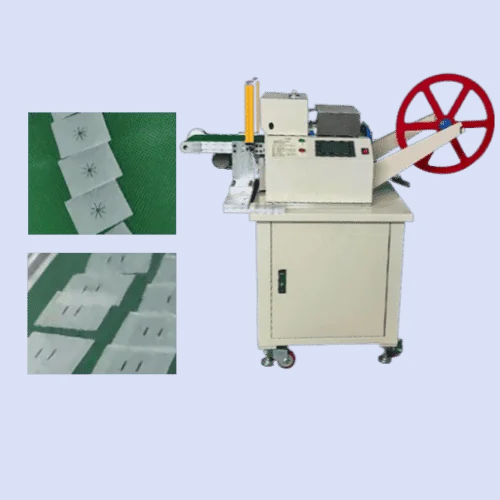

The HX-200DK-B2 is a versatile automatic punching machine designed for processing roll materials like EVA foam, sponge, rubber, and silicone sheets. It supports both full-cutting (punching through) and kiss-cutting (cutting the top layer while leaving the backing paper intact) for self-adhesive products.

With its high-precision feeding system, it is the ideal choice for manufacturing anti-skid pads, shock absorption gaskets, and electronic insulation components.

Key Features

- High Precision Feeding: Controlled by a micro-computer and stepper/servo motor, ensuring feeding accuracy within ±0.1mm.

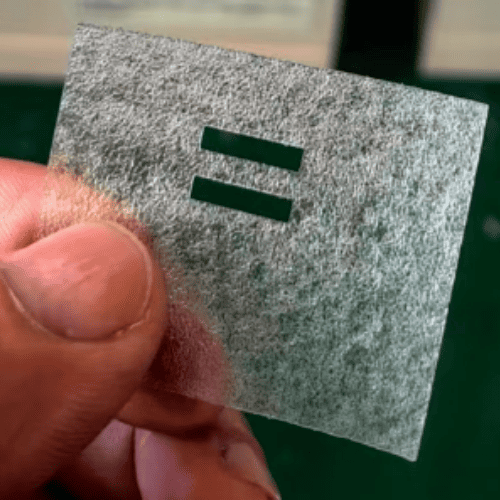

- Kiss-Cut Capability: Perfectly handles adhesive-backed EVA foam, cutting the gasket shape without damaging the release paper liner.

- Dual Functionality: Can be used for hole punching (die cutting) and length cutting depending on the mold setup.

- Waste Discharge: Supports automatic waste removal for punched holes, keeping the finished product clean.

- Gap Control: Features a nesting function to minimize the gap between cuts, significantly saving expensive raw materials.

- Compact Design: The B2 model offers a robust structure with a smaller footprint, suitable for efficient factory layouts.

Technical Specifications

| Model | HX-200DK-B2 |

|---|---|

| Max Material Width | 200 mm |

| Compatible Materials | EVA, Rubber, Silicone, PORON, Foam Tape |

| Punching Speed | 100 – 200 strokes/minute |

| Feeding Length | 0.1 – 9999 mm (Adjustable) |

| Cutting Pressure | 5 Tons / 10 Tons (Selectable) |

| Voltage | AC 220V, 50/60Hz, Single Phase |

| Die/Mold Type | Custom Wooden or Metal Die |

Applications

Widely used in the electronics, automotive, and furniture industries for:

- EVA Products: Furniture foot pads, anti-slip mats, packaging inserts.

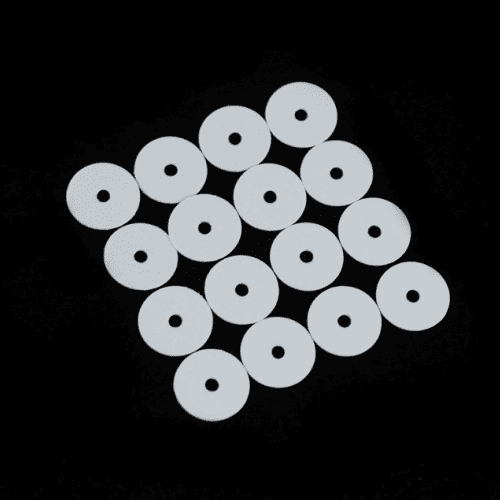

- Rubber/Silicone: Sealing gaskets, O-rings, flat washers.

- Electronic Accessories: 3M double-sided tape cutting, insulation paper, PET films.

- Shock Absorbers: PORON foam pads and buffer stickers.