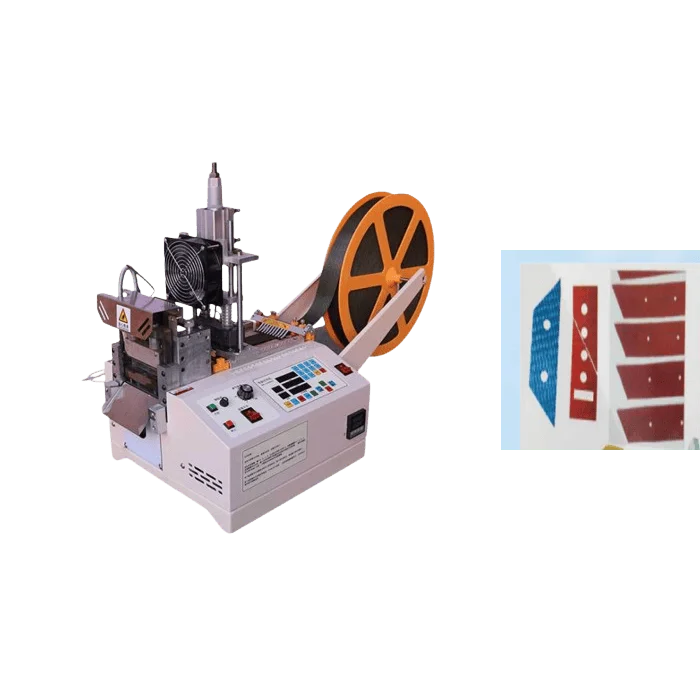

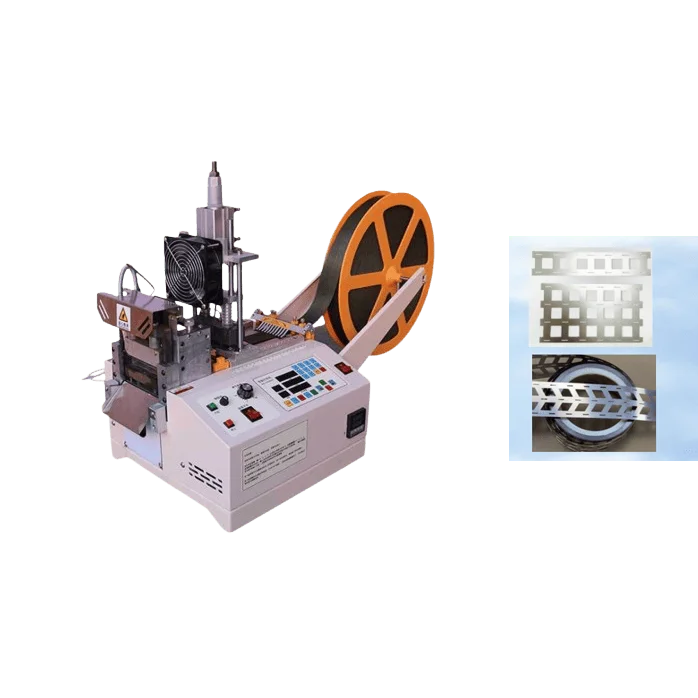

Fully Automatic Cutting and Punching Solution for Lanyards and Event Wristbands.

This machine is engineered to streamline the production of ID card lanyards, exhibition ribbons, and fabric wristbands. It combines automatic feeding, precise hole punching, and cutting in a single pass.

Whether you are producing heat-transfer printed lanyards or woven wristbands, this machine ensures clean sealed edges (preventing fraying) and perfectly centered holes for clips, safety breakaways, or RFID tags.

Key Features

- Cut & Punch Simultaneously: Automatically punches the hole (round, oval, or custom shape) while cutting the strap to length, saving labor time.

- Sealed Edges: Equipped with a high-temperature heating blade (or Ultrasonic option) to seal the fabric edges immediately, preventing loose threads.

- High Accuracy: Sensor-controlled feeding ensures the printed logo stays centered and the cut length is consistent within ±1mm.

- Versatile Molds: The punching die can be customized to make round holes for rivets, oval holes for clips, or jagged ends for wristbands.

- Batch Production: Set the quantity and speed on the PLC screen, and the machine works automatically until the batch is finished.

Technical Specifications

Model |

HX-200DK-D1(Series) |

|---|---|

| Max Cutting Width | 10mm – 50mm (Adjustable) |

| Cutting Length | 50mm – 9999mm |

| Punching Shape | Round Hole (3mm-5mm), Oval Hole, or Custom |

| Cutting Method | Hot Knife / Cold Knife (Optional) |

| Production Speed | 60 – 100 pcs/minute |

| Temperature | Adjustable (Max 400℃ for Hot Cut) |

| Voltage | AC 220V / 110V, 50/60Hz |

Applications

Perfect for manufacturing:

- Exhibition Lanyards: Polyester ribbons for ID badges and card holders.

- Event Wristbands: Fabric festival bracelets and RFID wristbands.

- Medal Ribbons: Neck ribbons for sports medals.

- Promotional Straps: Mobile phone straps and keychain lanyards.