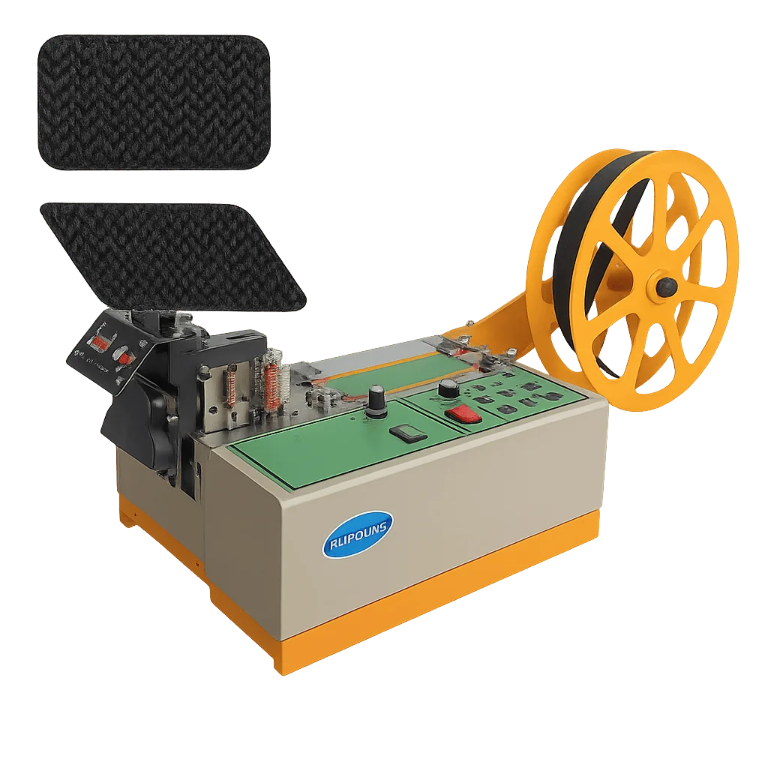

Dual-Mode Automatic Cutting Machine: Hot Sealing for Synthetics & Cold Cutting for Leather.

The HX-200 Hot and Cold Cutting Machine offers the ultimate versatility for textile and heavy-duty strap manufacturers. It allows operators to switch between Hot Cut Mode (to seal edges of Nylon/Polyester webbing prevents fraying) and Cold Cut Mode (for Leather, Velcro, PVC, and Cotton tapes) instantly.

With a cutting width of up to 200mm, it is powerful enough to handle seat belts, heavy lifting straps, and pet collars with ease.

Key Features

- Hot & Cold Dual System: One machine does it all. Turn on the heater to seal synthetic webbing; turn it off for cutting zippers, leather, or velcro.

- Automatic Operation: Set the length, quantity, and speed, and the machine cuts automatically, stopping when the batch is complete.

- Sealed Edges (Hot Mode): The high-temperature blade melts and seals the end of nylon/PP straps, ensuring no loose threads or fraying.

- Heavy Duty: Robust construction capable of cutting thick webbing, seat belts, and bag straps.

- Memory Function: Automatically saves the settings (Length, Speed, Quantity) even if the power is turned off.

Technical Specifications

| Model | HX-200 (Hot & Cold) |

|---|---|

| Max Cutting Width | 200 mm |

| Cutting Mode | Hot Cut (Heating) / Cold Cut (No Heating) |

| Max Temperature | Up to 350℃ – 400℃ (Adjustable) |

| Cutting Length | 1 – 9999 mm |

| Cutting Speed | 80 – 110 cuts/minute |

| Voltage | AC 220V / 110V, 50/60Hz |

| Blade Material | Imported High-Speed Steel (HSS) |

Applications

Suitable for a wide range of strip materials:

- Hot Cut (Sealing): Nylon webbing, Polyester tape, PP straps, Seat belts, Parachute cord, Braided rope.

- Cold Cut: Leather strips, Velcro tape, Cotton tape, Zipper, PVC tube, Plastic film.