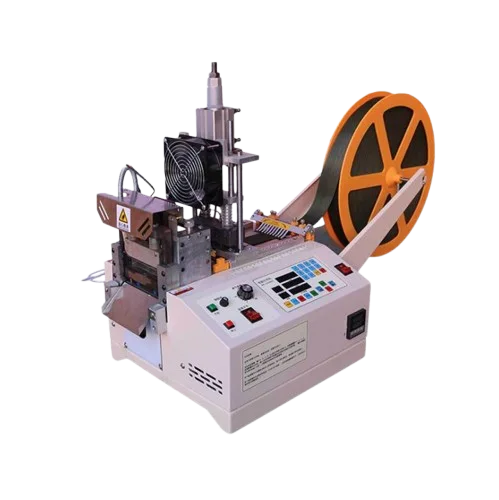

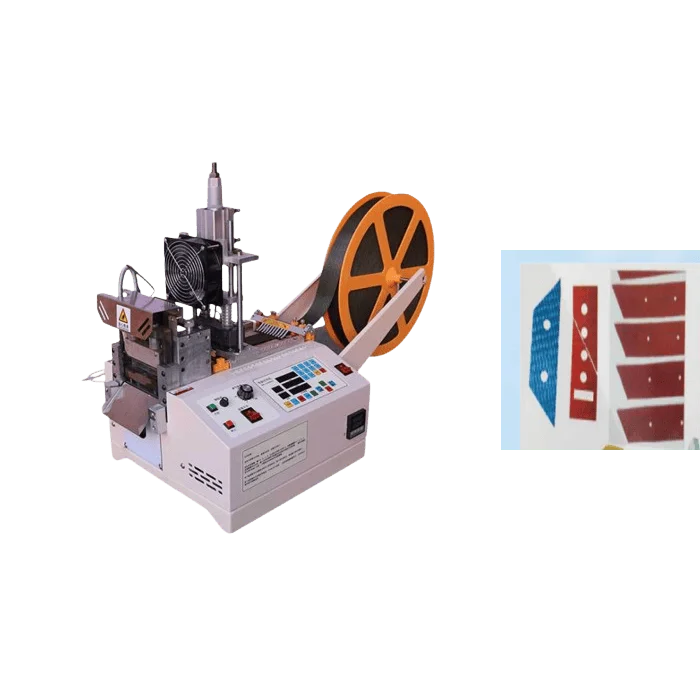

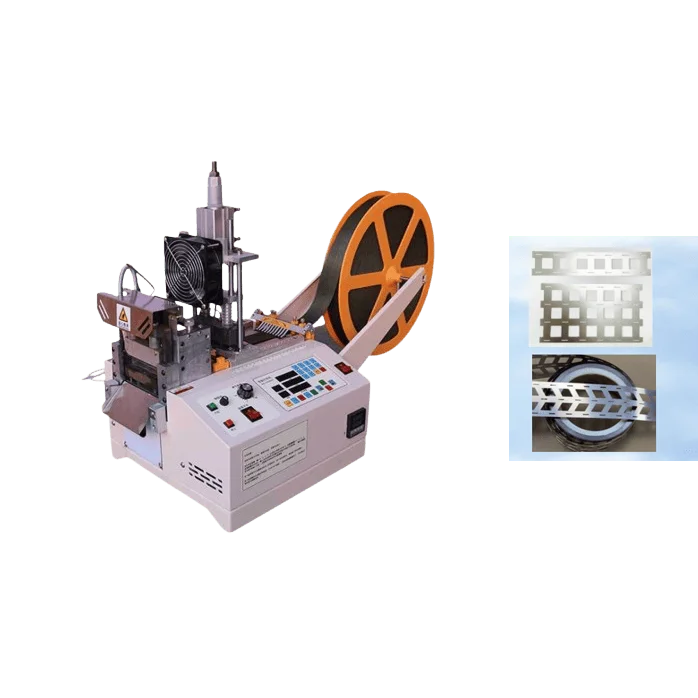

The HX-200DK-B1 Webbing Nylon Punching Holes Cutting Machine is designed for manufacturers who need clean cuts, accurate holes, and stable production when processing nylon webbing and strap materials.

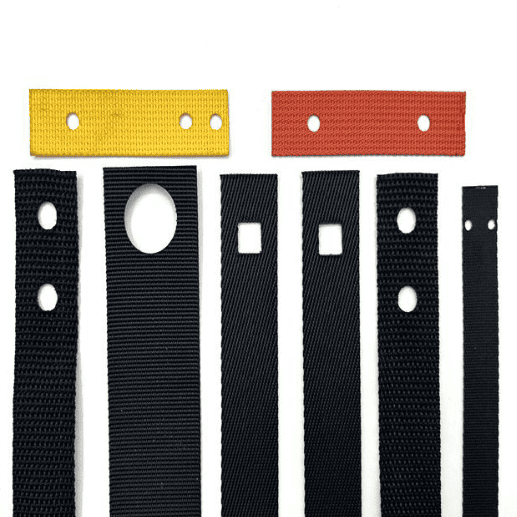

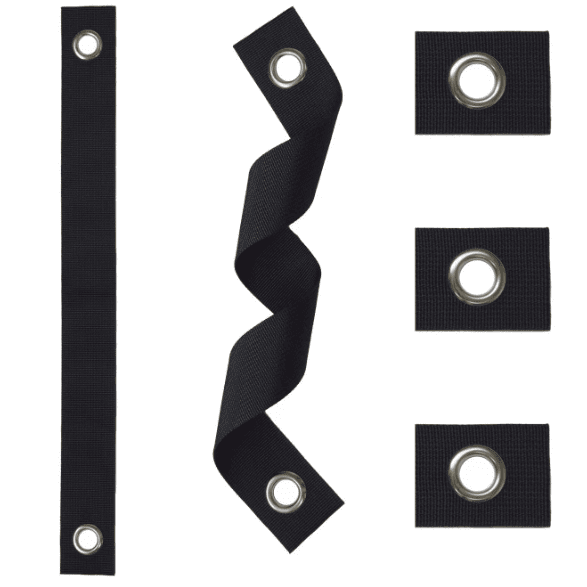

This machine combines hot knife cutting and pneumatic hole punching in one automated process. While cutting the webbing to length, it punches precise holes and seals the edges at the same time—preventing fraying and reducing secondary operations.

The result is a faster workflow, consistent product quality, and strap components that are ready for assembly.

Key Benefits

-

Cut and Punch in One Step

Eliminates the need for separate punching and cutting stations, saving time and labor. -

Clean, Sealed Edges

Hot knife cutting (up to 400°C) prevents loose threads and delivers a professional finish. -

Accurate Hole Positioning

Pneumatic punching ensures stable force and repeatable hole placement. -

Reliable Length Accuracy

Micro-computer control with stepper motor achieves ±0.1 mm cutting accuracy. -

Easy and Safe Operation

Automatic stop function protects the machine when material runs out.

Built for Production

The HX-200DK-B1 is built with a heavy-duty pneumatic cylinder that handles thick and high-density webbing with ease. The PLC touch screen allows operators to quickly set cutting length, quantity, and speed, making it ideal for both small batches and continuous production.

By reducing manual handling and combining multiple processes into one machine, manufacturers can improve efficiency while maintaining consistent output quality.

Typical Applications

-

Safety belts and industrial straps

-

Pet leashes, collars, and harnesses

-

Backpack and luggage webbing

-

Medical and rehabilitation straps

-

Outdoor and tactical gear

Suitable Materials

-

Nylon webbing

-

Polyester webbing

-

Safety belt tape

-

Woven straps and straps with heat-sealable edges

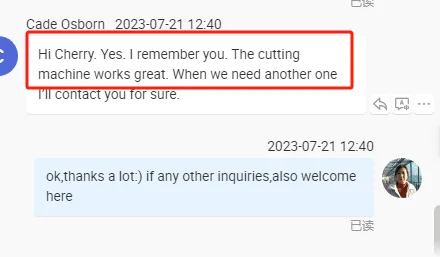

Why Buyers Choose HX-200DK-B1

-

One compact machine replaces multiple workstations

-

Consistent results with minimal operator intervention

-

Reduced labor cost and production time

-

Clean, assembly-ready strap components

-

Proven solution for webbing-based products