Optimize Your Production: High-Precision Automatic Die Punching for Insulation Gaskets.

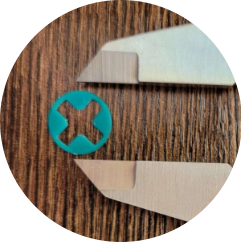

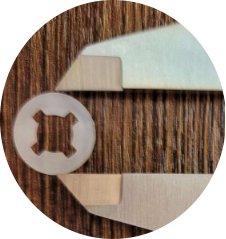

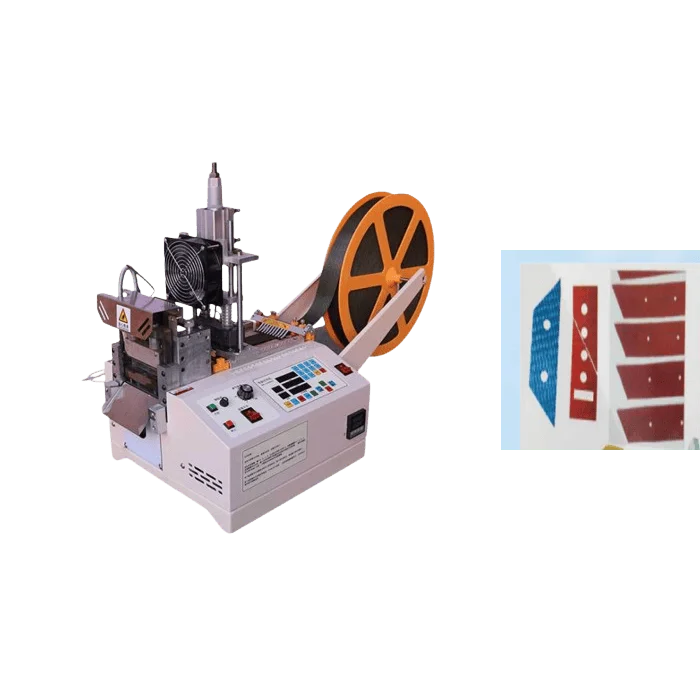

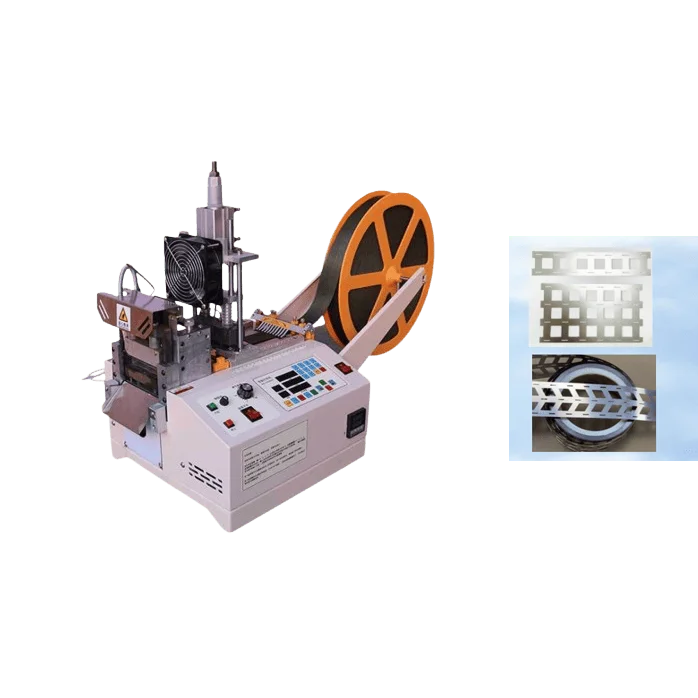

This machine is specifically engineered for the high-speed manufacturing of PVC screw insulation gaskets, plastic sealing washers, and non-metallic flat seals. Equipped with a precision feeding system and high-force punching mechanism, it ensures burr-free edges and accurate dimensions for every single piece.

It is the ideal solution for manufacturers in the hardware, automotive, and electronics industries looking to replace manual labor with automated efficiency.

Key Features & Benefits

- High Efficiency: Punching speed up to 150-250 strokes/minute (depending on material size), boosting daily output significantly.

- Versatile Material Handling: Perfect for PVC, PET, Teflon (PTFE), Nylon, Rubber, Fastbar paper, and other insulation materials.

- Precision Cutting: Advanced servo/stepper motor feeding ensures cutting accuracy within ±0.1mm.

- Cost Saving: Supports multi-cavity molds (punching multiple gaskets at once) to maximize material usage and reduce scrap.

- Easy Operation: User-friendly interface allows quick setup of speed and quantity.

Applications

This machine is widely used to produce:

- PVC / PE / PP Insulation Gaskets

- Nylon Washers (M3, M4, M5, etc.)

- Rubber Flat Seals & O-rings

- Meson Gaskets & Electronic Insulators

- Double-sided Tape Die Cutting

Looking for a Customized Gasket Making Solution?

We provide full support including machine setup and custom die/mold manufacturing based on your drawings.