Efficient Roll-to-Sheet Cutting Solution for Packaging Materials and Plastic Films.

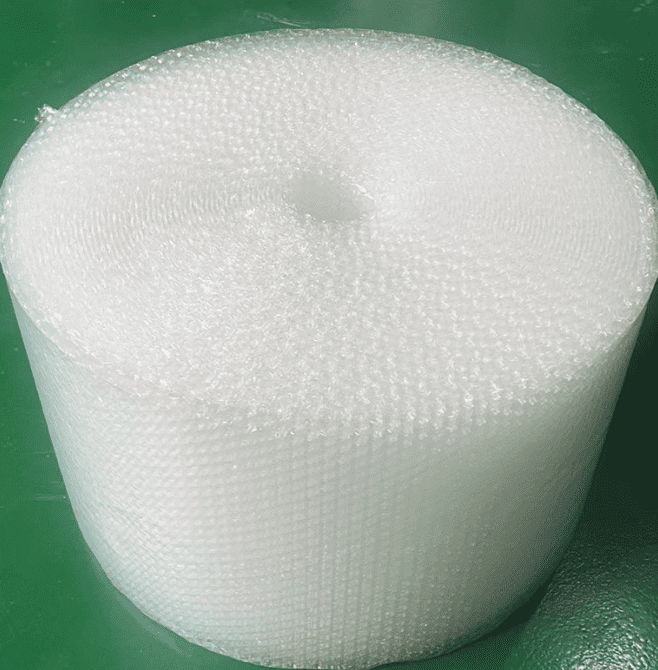

The HX-500 Automatic Cutting Machine is widely used in the packaging industry to cut large rolls of Bubble Wrap (Air Bubble Film), PVC Film, EPE Foam, and Plastic Sheeting into specific lengths.

It eliminates the need for manual cutting with scissors or utility knives, ensuring perfectly straight edges and consistent sheet sizes. It is an essential machine for e-commerce warehouses, packaging factories, and electronic assembly lines.

Key Features

- Wide Cutting Capacity: With a max feeding width of 500mm, it can handle most standard rolls of packaging films and foam sheets.

- Automatic Operation: Simply input the desired length and quantity on the computer panel, and the machine works automatically.

- High-Speed Feeding: Equipped with dual rubber rollers to feed slippery plastic materials smoothly without scratching or slipping.

- Clean Cut: Uses a durable high-speed steel (HSS) blade to provide a clean, square cut on thin films and thick bubble wraps alike.

- Static Elimination (Optional): Can be equipped with an anti-static device to prevent thin films from sticking to the blade.

- Batch Memory: Automatically stops when the preset quantity is reached.

Technical Specifications

| Model | HX-500 Micro-computer Cutting Machine |

|---|---|

| Max Cutting Width | 500 mm (Other sizes: 360mm, 600mm, 800mm available) |

| Cutting Material | Bubble Wrap, PVC/PE/PET Film, EPE Foam, Paper |

| Cutting Length | 0.1mm – 9999.9mm (High Precision) |

| Cutting Speed | 80 – 120 cuts/minute |

| Accuracy | ±0.1 mm |

| Voltage | AC 220V / 110V, 50/60Hz |

| Power | 500W |

Applications

This machine is suitable for sizing materials such as:

- Packaging: Air bubble film, EPE pearl cotton foam, EVA foam sheets.

- Plastic Films: PVC, PET, PP, PE, PI insulation films.

- Paper: Kraft paper, release paper, insulating paper.

- Others: Aluminum foil, copper foil, conductive fabric.