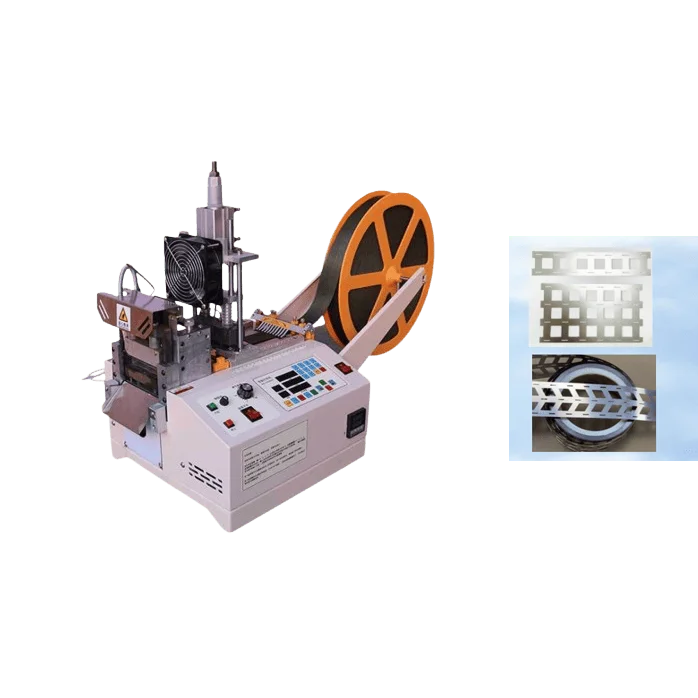

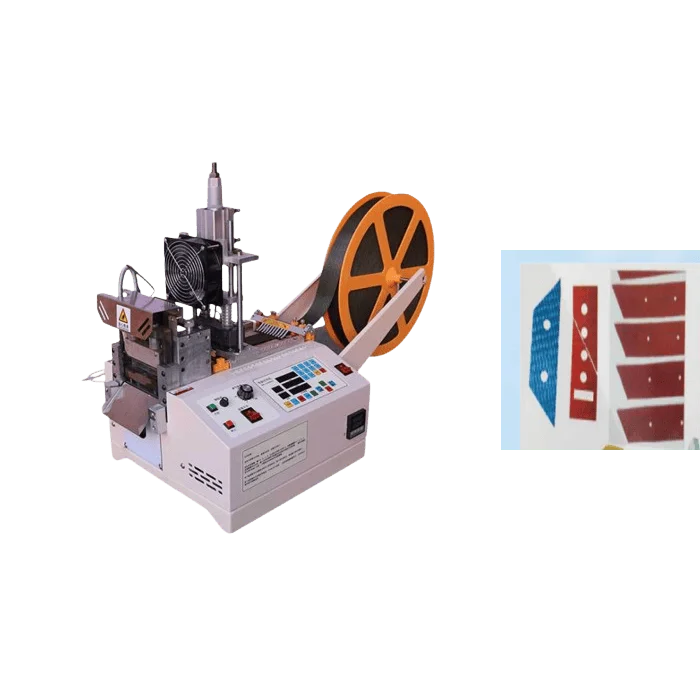

Advanced Automatic Punching and Cutting Machine for Battery Interconnects.

The HX-200DK-E2 is an upgraded industrial cutting machine designed to process roll materials for the energy sector. It excels at cutting and punching Nickel Strips, Copper Tabs, and Aluminum foils used in high-capacity lithium battery packs.

Featuring a robust feeding mechanism and high-hardness blade, the E2 model ensures precise length control and clean cut edges, helping manufacturers assemble battery packs (for EVs, E-bikes, and Energy Storage) with higher efficiency and safety.

Key Features

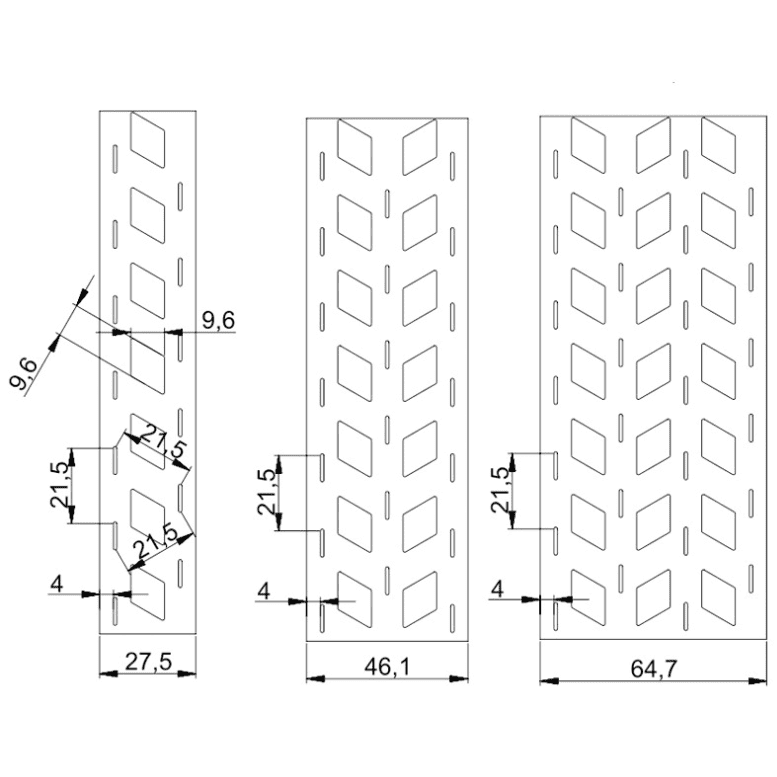

- Dual-Function Capability: Integrates automatic feeding, hole punching (with mold), and cutting into one seamless workflow.

- Hardened Blade System: Uses specialized SKD-11 or Tungsten Steel blades to cut through tough metal strips without frequent sharpening.

- High Precision: Computer-controlled feeding system ensures a cutting tolerance of ±0.1mm, essential for automated welding lines.

- Waste Management: Designed to handle waste discharge effectively when punching holes in the strip.

- Memory Function: Stores multiple batches of data (length, quantity, speed) for quick setup changes between different battery models.

Technical Specifications

| Model | HX-200DK-E2 |

|---|---|

| Max Material Width | 200 mm |

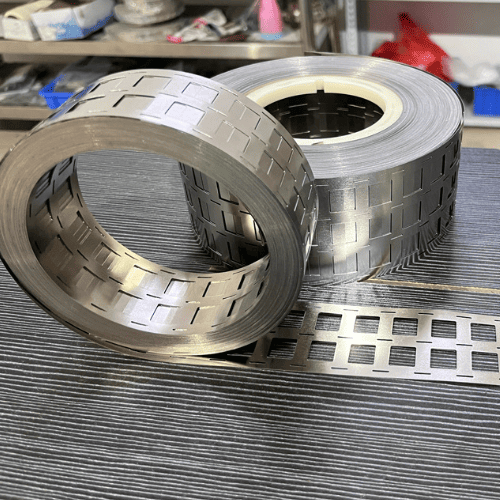

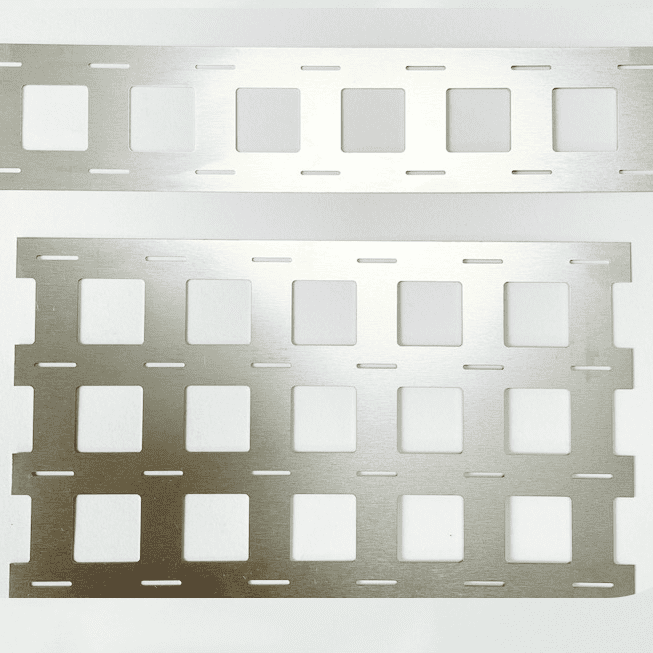

| Applicable Material | Pure Nickel, Nickel-Plated Steel, Copper, Aluminum |

| Material Thickness | 0.1mm – 0.5mm (Depends on hardness) |

| Cutting Precision | ±0.1 mm |

| Cutting Speed | 60 – 110 cuts/minute |

| Mold Type | Customizable Punching Die |

| Voltage | AC 220V / 110V, 50/60Hz |

Applications

Targeted for the battery and electronics industry:

- Battery Assembly: Connection strips for 18650, 21700, and prismatic cell packs.

- Energy Storage: Busbars for solar battery walls and large energy storage systems.

- Electronic Parts: Metal shims, spacers, and grounding tabs.