How to Cut Nylon Webbing Without Fraying: The Heavy-Duty Guide

If you are manufacturing cargo straps, dog leashes, or military tactical gear, you are likely working with Nylon Webbing. Unlike the delicate satin we discussed in our Polyester Ribbon guide, Nylon is a beast. It is thick, tough, and notorious for unraveling violently if cut incorrectly.

To cut Nylon webbing without fraying, you must use a high-temperature Hot Knife or an Automated Guillotine with a heating element. Nylon has a melting point of approx. 220°C but requires significant thermal energy to penetrate its dense weave. A proper cut must cauterize all layers of the webbing instantly to prevent the "blooming" effect where inner fibers explode outwards.

I am Cherry Chan, and at HAOXINHE, our webbing tape cutting machine1 series is specifically tuned to handle these heavy-duty materials for clients worldwide.

[👉 https://cutopix.com/product/?product_category=tape-webbing-cutting-machine: Automatic Webbing Tape Cutting Machine]

Why is Nylon So Difficult to Cut?

Nylon (Polyamide) is hydroscopic (absorbs moisture) and extremely strong. In webbing form, it is woven in multiple layers (tubular or flat).

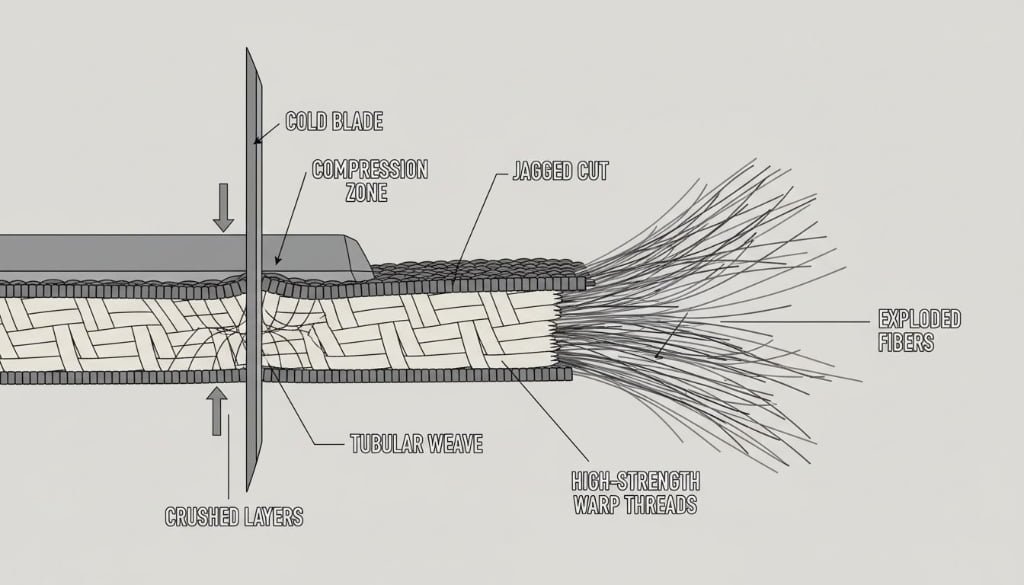

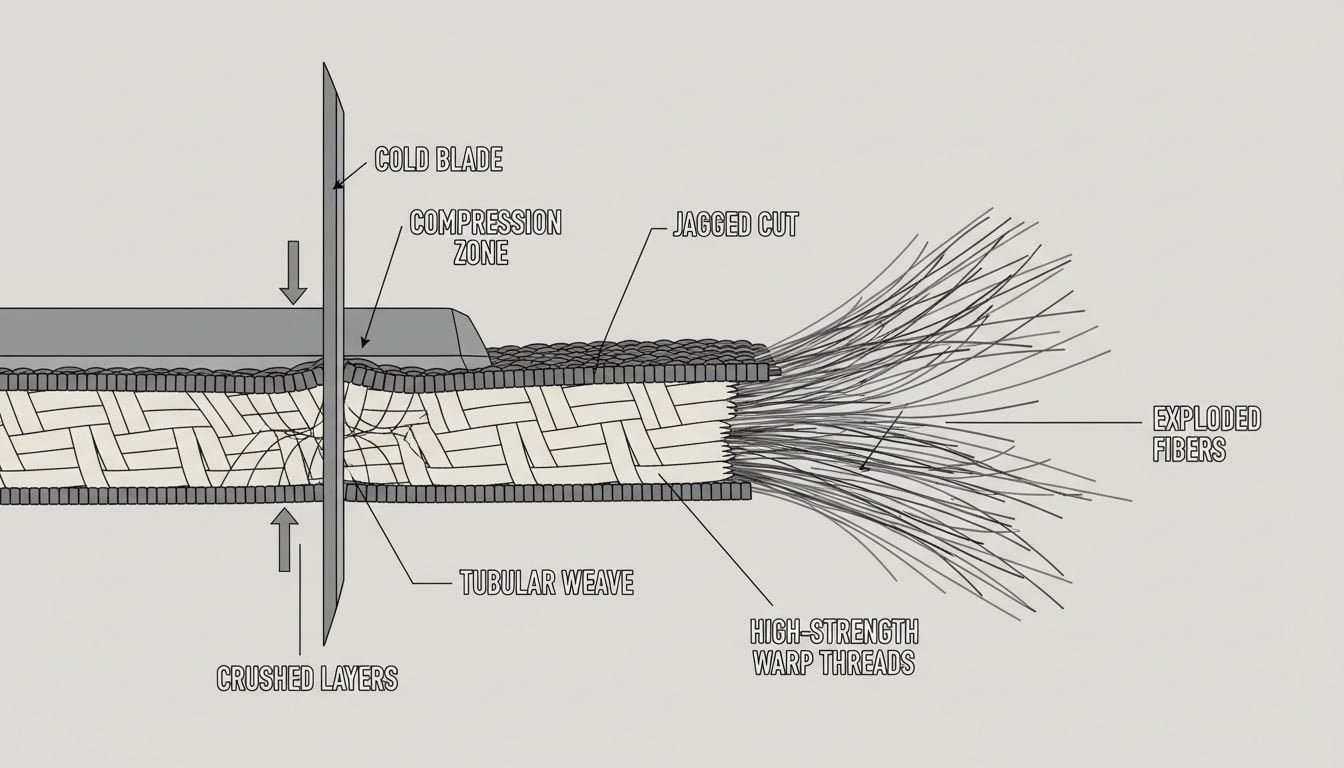

When you try to cut this with a cold blade or a standard pair of scissors:

- The Crush Effect: The blade crushes the top layer before cutting the bottom layer, creating an uneven, jagged edge.

- The Explosion: Once the tension is released, the thick warp threads spring back, creating a "broomstick" end that is impossible to thread into a buckle.

Unlike the simple polyester ribbon which is thin, Nylon webbing acts like a solid block of plastic that needs to be sliced.

Available Methods: Industrial Solutions

Forget handheld lighters. For Nylon webbing, you need power.

1. Heavy-Duty Hot Knife2 (The Guillotine Style)

For webbing thicker than 1mm, a standard "scissor-action" hot knife is not enough. You need a Vertical Guillotine Hot Knife2.

- How it works: A massive, heated wedge blade descends vertically onto the webbing.

- Why it works: The weight and heat (300°C+) force the seal through all layers simultaneously.

- Result: A solid, fused block at the end of the strap.

2. Rotary Bevel Cutting3 (The Angled Cut)

Often, nylon straps need to be cut at an angle (45 degrees) to make them easier to insert into buckles.

- The Machine: Our rotary bevel cutting machine allows the blade head to rotate.

- The Challenge: Cutting an angle increases the surface area. The blade needs more heat and more time to seal a 45-degree cut than a straight cut.

[👉 https://cutopix.com/product/hx-chs05-webbing-straight-beveling-hot-cutting-machine/: Rotary Bevel Cutting3 Machine]

Comparison Table: Nylon vs. Polyester Cutting

| Feature | Polyester (Satin/Grosgrain) | Nylon (Heavy Webbing) |

|---|---|---|

| Melting Point | ~250°C | ~220°C |

| Blade Required | Thin, Sharp Hot Blade | Thick, Heavy Wedge Blade |

| Cutting Pressure | Low | High (Pneumatic assist often needed) |

| Fume Generation | Low | High (Nylon smoke is stronger) |

| Cooling Time | Instant | Needs 1-2 seconds to "set" |

Industrial / Manufacturing Considerations

Processing Nylon creates specific manufacturing challenges that you don’t see with lighter ribbons.

1. The Smoke Problem

Nylon releases distinct fumes when melted. In a factory with 50 lines, this is a health hazard.

- Solution: HAOXINHE machines can be equipped with smoke extraction ports. We strongly advise our European clients to install local exhaust ventilation over their hot and cold cutting machine stations.

2. The "Sticky Blade" Issue

Because Nylon melts into a thick goo, it tends to stick to the blade. If the blade gets dirty, the heat transfer fails, and the cut becomes messy.

- Cherry’s Tip: We coat our blades with a special Teflon-like high-temp coating4. However, operators must still clean the blade with a copper brush every 4 hours. It’s a maintenance discipline.

3. Automatic Punching

Many nylon straps need holes for grommets. Doing this as a secondary step is a waste of time. Our automatic punching cutting machine5 burns the hole and cuts the length in the same pass. The hole is also heat-sealed, so it won’t tear under load.

[👉 https://cutopix.com/product/hx-95m-hot-cold-ribbon-label-plastic-cutting-machine/: Automatic Punching and Cutting Machine]

How Machines Solve This Problem

For Nylon Webbing6, you need torque and thermal mass. A toy machine won’t cut it.

The HAOXINHE HX-160 Heavy Duty edition is designed for this.

- Pneumatic Power: We use air cylinders to drive the blade down, providing 10x the force of a standard electric motor. This ensures the blade goes through the nylon, not just rests on it.

- Pre-Feeding System: Heavy rolls of webbing (50kg+) create drag. If the machine pulls too hard, the length varies. We use an active pre-feeder to slacken the webbing before it enters the cutter.

- Blade Geometry: We use a "V" shape or a thick Wedge shape blade specifically for Protective Foam Cutting Machine and Heavy Webbing applications to retain heat.

We also offer metal pipe cutting and beveling machine logic applied to our stiffest webbing cutters—treating the webbing almost like a solid pipe to ensure a square cut.

Conclusion

To summarize, cutting Nylon Webbing is a heavy-duty operation. You need a machine with pneumatic power, smoke extraction, and a high-mass heating blade. Do not compromise with light-duty ribbon cutters, or your blades will bend and your edges will fail.

Cherry’s Insights for Google Snippet

To cut Nylon Webbing without fraying, you must use a heavy-duty Hot Knife machine capable of reaching 300°C with high cutting pressure. Unlike thin ribbons, nylon webbing requires a ‘wedge-shaped’ blade to penetrate and fuse the thick woven layers simultaneously. For mass production, HAOXINHE recommends Pneumatic Hot Cutters (Air-driven) rather than standard motor-driven cutters, as the extra force ensures a clean, sealed edge through the dense material.

-

Find top-rated machines designed specifically for cutting webbing tape effectively. ↩

-

Learn about the technology behind Hot Knives and their effectiveness in cutting tough materials. ↩ ↩

-

Understand the benefits of Rotary Bevel Cutting for angled cuts in various materials. ↩ ↩

-

Discover how Teflon-like coatings improve the performance and longevity of cutting blades. ↩

-

Find out how these machines streamline production by combining cutting and punching in one step. ↩

-

Explore the versatility and strength of Nylon Webbing, essential for various manufacturing needs. ↩

[…] Cutting Goal: Controlled Melting. We want to fuse the warp and weft threads together to stop fraying. […]

It is ok, we can share with you video of cutting machine.Whatsapp: +8613270987536